Lapidary Machine Restoration

If you are not intending to buy any equipment, or have any equipment restored, please don't ask questions about anything listed on this page, your saw, your buddy's saw, any other lapidary equipment, etc. I simply don't have the time to answer questions about someone else's equipment so I will NOT respond! (yeah I know someone ignores this at least once a week)

Due to popular demand I've added this page to showcase my restored/refurbished lapidary equipment. These are examples only, all of it has been sold or is humming away in my shop :) I will do restorations for you if you can do the following:

Bring me a piece of equipment to restore, I'm in Oregon City OR. If you want to ship it here that's fine, but I will charge extra to ship it back to you. It can be a pretty well roached machine as long as the parts are all there. (I've seen the Ebay sellers call these "well loved". Yeah right, if someone loved their equipment it wouldn't have been left out in the rain for a decade). If it has gaping holes or is just a shell with few or no parts you should recycle it. I can't do things like make a shaft for a cabochon machine or slab saw. I can tear apart and replace most everything else with usable parts. I'll try to find them if I have to. Decide what you want to end up with: A useable machine that you will hook up to a motor? A fully functional machine with a base (if applicable) and a motor? A machine that looks like it came from the factory complete with all the original bells and whistles? A machine in great shape that will last a lifetime? (Almost all the restorations I do fit into this category). I really prefer to do these, I will send someone home with a "plug and play" machine that they can plug into a receptacle and use right now. I don't charge a flat fee for labor, and extra for parts and a bit for hardware (bolts nuts washers etc.). I can paint or not paint, but if it's rusty it will keep rusting forever. I will put a coat of priming paint on those to stop rusting. Some machines require a few fixes or a modification or two to get them up and running. Others like big saws require a few weeks tearing down and rebuilding from the bottom up. I'm not doing this to turn a giant profit, I just really like doing it although when I'm busy it might take a while.

Please note (and this is important) The value of the machine has exactly nothing to do with what you paid for it. If you overpaid, I feel sorry for you. If you got a great bargain, congratulations! So my charges have everything to do with restoring a solid machine that works as intended, and nothing to do with the price if you paid or want to sell it at.

Virtually all of my equipment these days is being prepaid by customers who want a restored machine. If I find equipment for a great price that no one wants to prepay for, it will end up on the Equipment For Sale page. If you want a specific machine and are willing to PREPAY my up front labor for it (a ballpark estimate), and invoice you for the parts etc. after it's finished(if I find that I can't restore it to my satisfaction then I'll reimburse you for the cost of the machine)

I am restoring machines most of the time, so if you want a machine restored, CONTACT ME HERE and I'll put you in line next. to get started!

It needs to be a relatively common machine used in lapidary work. Examples include (example machines are here; I have done many more than these, but the pics have been lost to various hard drive crashes (:

(click on the name to see the examples)

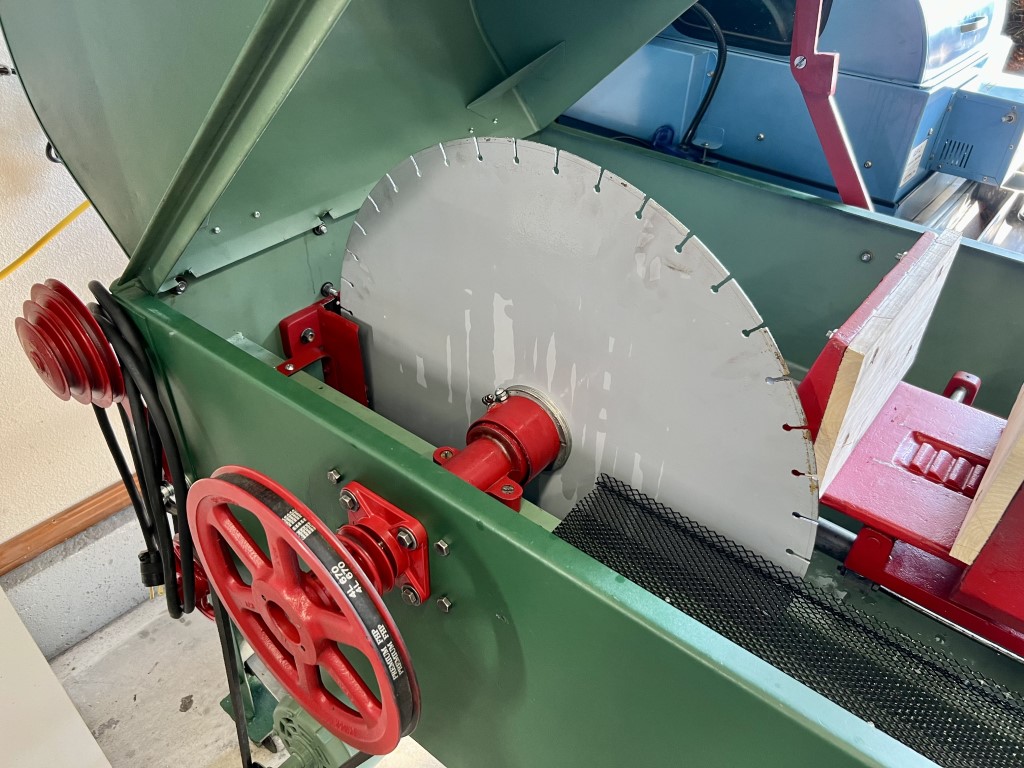

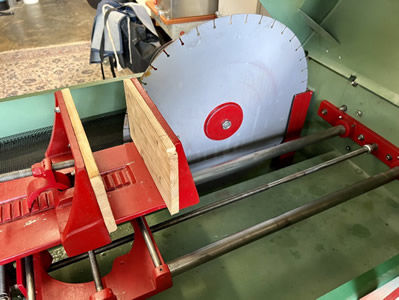

- Slab saws - in an enclosed cabinet (usually), anywhere from 12"

on up to 36" if you have a moving van to bring it! This include "drop" or "chop" saws where the blade is mounted on an arm that lowers onto the rock.

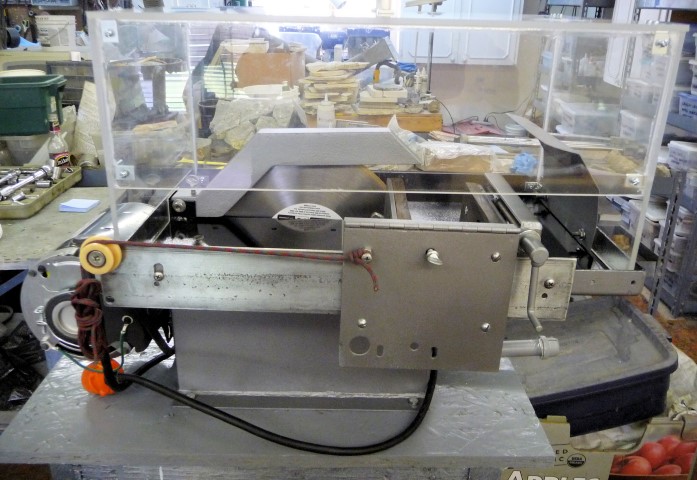

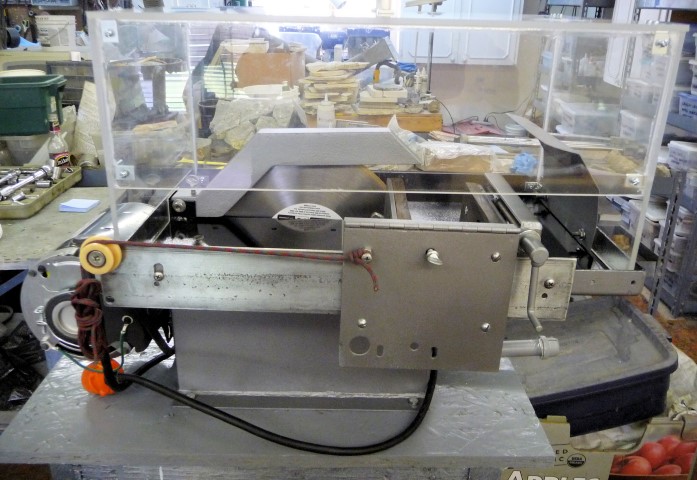

- Trim saws - from 4" to (usually) 12" with a table that you can push the vise, or a feed motor or weight that pulls the vise into the blade. Some of these can be enclosed with a drop on lid (I have actually made plexiglass lids), but technically they are trim saws becasue they don't have a hinged lid and aren't really intended to slab larger rocks.

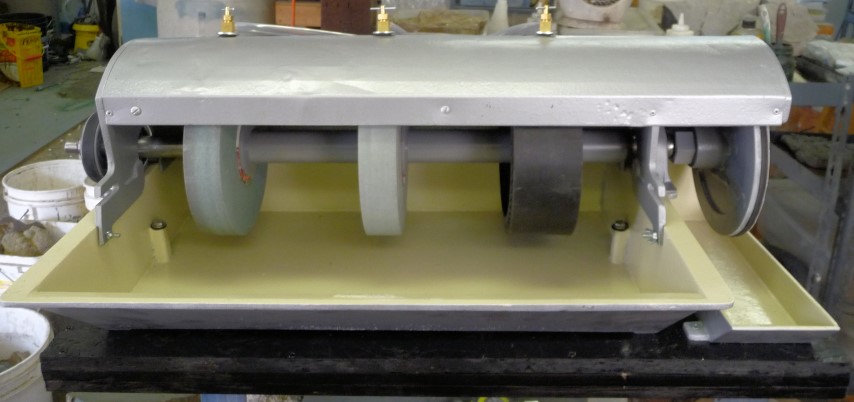

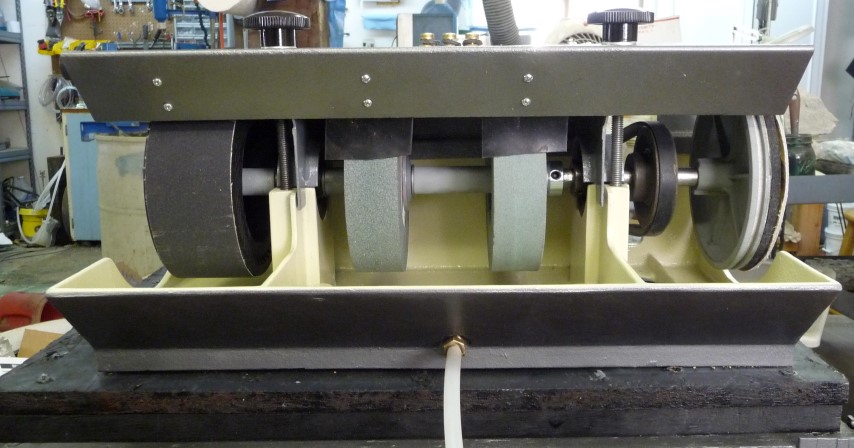

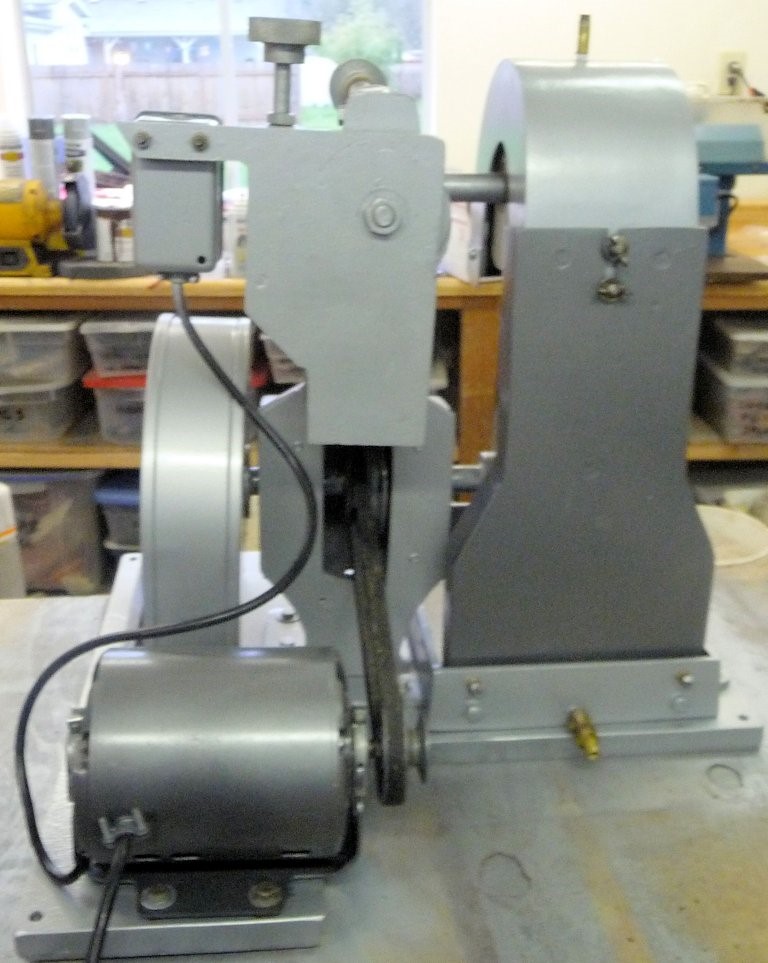

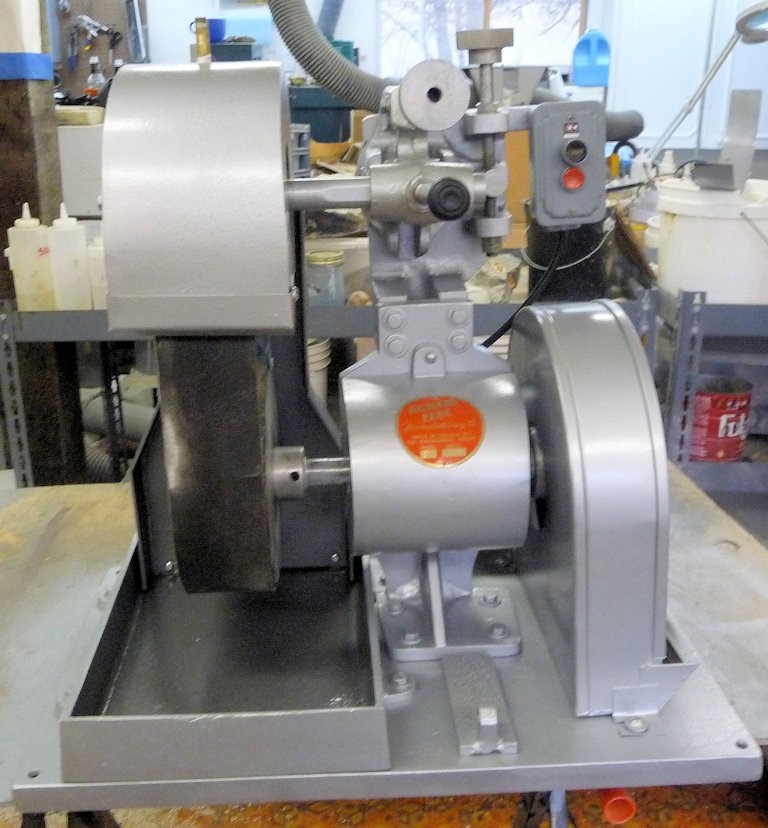

- Cabochon machines - have a shaft with wheels or drums in a pan that holds water and a drip or water spray system, usually 6" or 8" wheels. There can be anywhere from one wheel (rare) to 6 wheels (also rare). Most machines have 2 to 4 wheels. There may be a polishing or sanding disk on one or both ends. Some really popular models are the Diamond Pacific Genie/Titan/Pixie, Cabmate, Cabking, and EZ Cab. Please note: I don't do bare arbors (e.g. Poly) because they need a pan and water drip system to become a true lapidary machine. I could do that but it's really not cost effective. They are pretty cheap used because the person selling it realized that can't use it for lapidary without building the rest of the machine around it.

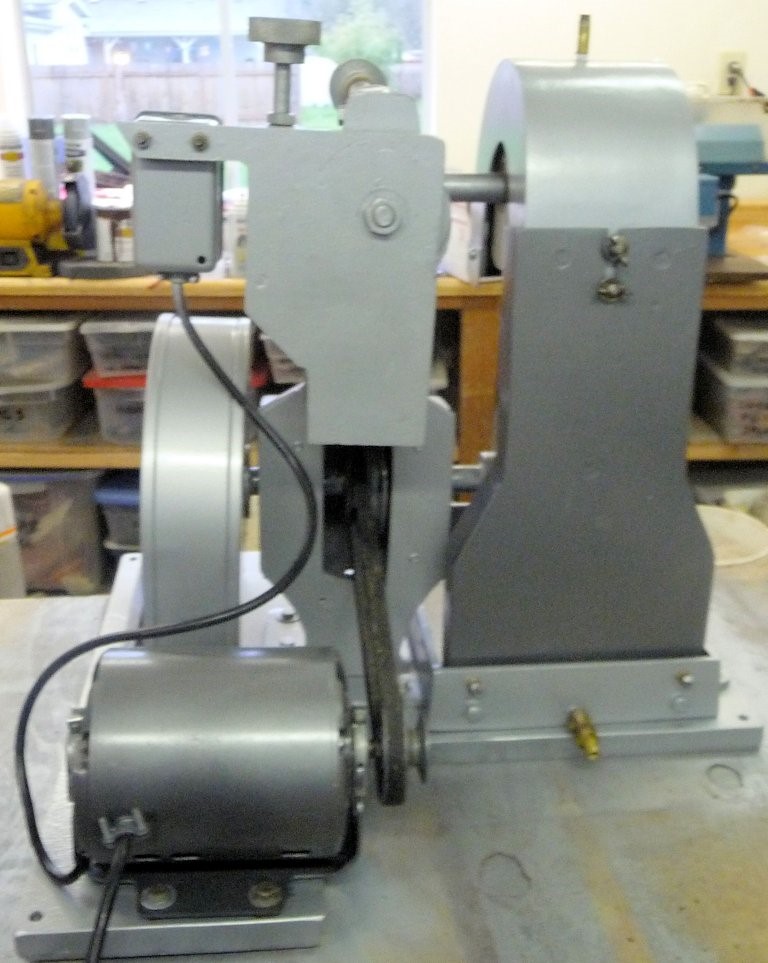

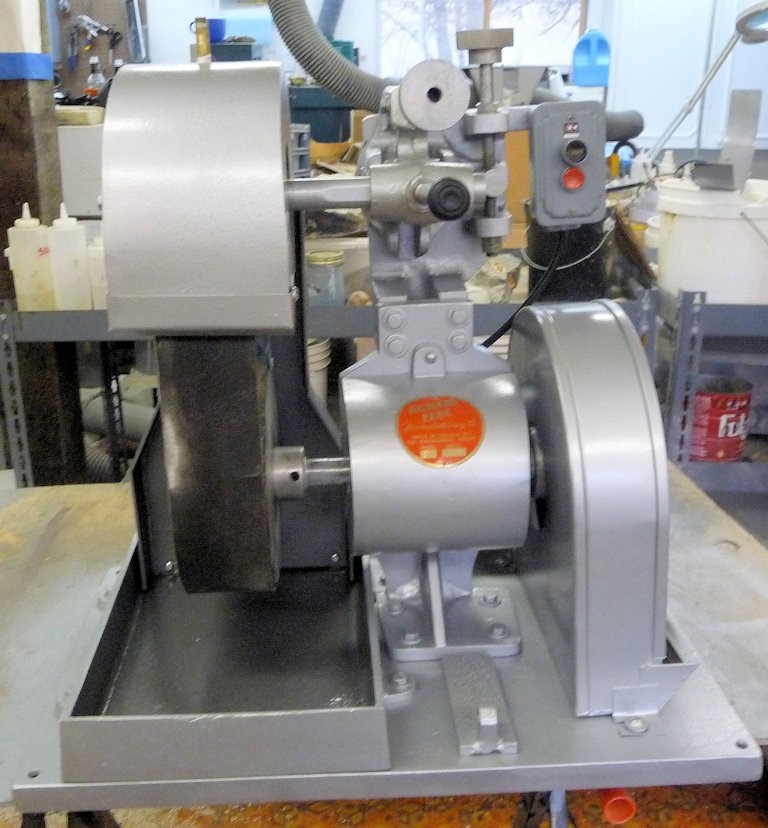

- Combination machines - a cabochon machine with one or more attachments on a single shaft. There are many types but they usually have a trim saw, a cabochon machine, and/or a buffung wheel or polishing head.

- Sphere machines - these are pretty rare beasts but generally have 2 or 3 motors with a cup and grind preformed rocks to a spherical shape. They do tend to go sideways but that's usually a straightforward fix. Most of the time they're rusted from the constant water drip. I can refit the heads with all diamond pads (saves a ton of time and is generally hassle free).

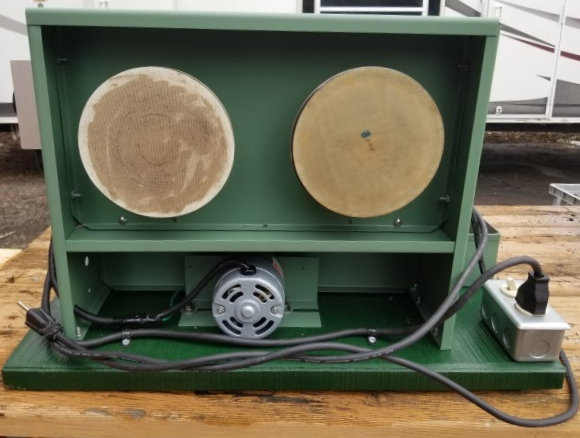

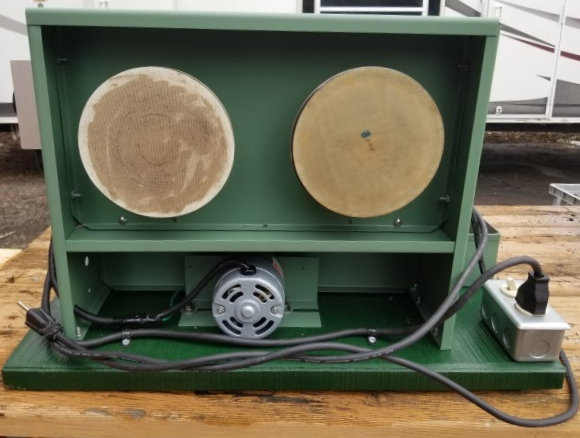

- Polishing or buffing wheels - usually a large, slow rotating wheel with a leather or felt cover that uses a polishing compound (cerium oxide is far and away the best).

I've restored a dozen of these and even built a couple. If you polish flat pieces or cabochons they are ABSOLUTELY THE BEST STAND ALONE MACHINE TO USE.

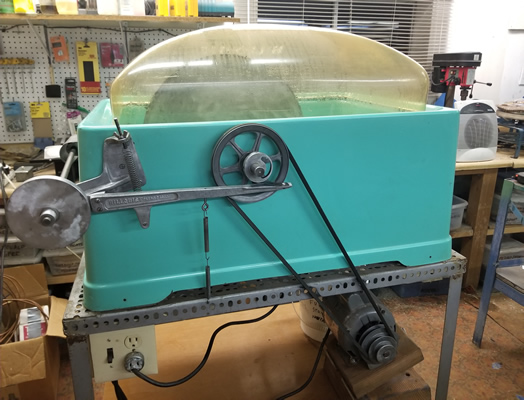

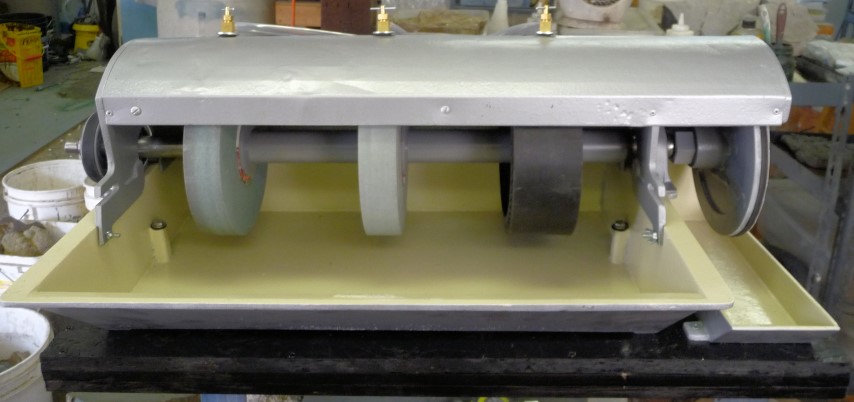

- Vibratory Flat Laps - vibrating flatlaps with one or 2 pans.

I've done a ton of these and can usually crank it out fast, they are very simple machines (that cost a fortune new from the factory).

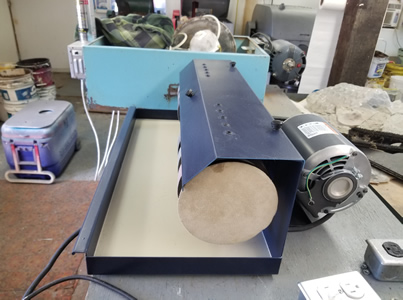

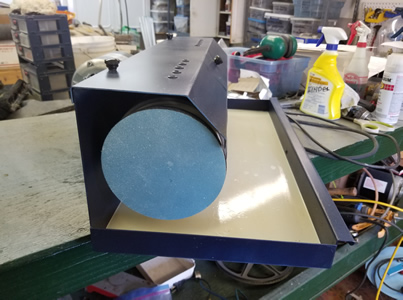

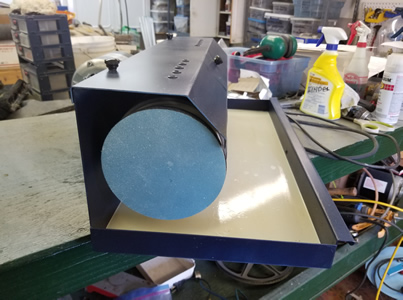

- Sanders - most have a vertical sanding belt with a water drip system, but some can be vertical disk dry sanders. I have a high speed overhead dry sander that is a real workhorse for sanding flat faced rocks or thick slabs, and I've restored at least 5 of them.

- Tumblers - Barrel tumblers (like a Lortone) with a barrel that rotates on 2 rollers. These are very simple machines and it doesn't take long to restore one.

Vibratory tumblers (a bowl on top of a stand that houses a motor) are a different beast but not that difficult to restore.

- Flat Laps - a rotating disk or plate mounted horizontally on a base. There aren't all that common but are easy to restore.

I've wanted a 14" for decxades and can't find one that isn't an astronomical price!

- Faceting Machines - I will absolutely not work on them. These require a very experienced technician to get them accurate enough to be useful.

And don't let anyone tell you otherwise. "Restored" or "Works good" does not in most cases mean "functions as intended"! It's more of an art than a science to get a machine into a condition that is capable of cutting perfect gemstones.

And I am not a faceting maching artist!

The Way I Do Restorations

(I don't believe in selling "you fix it" machines so I don't partially restore or sell any) Every piece is completely disassembled, sanded to remove all traces of rust and loose paint, primed, painted and clear coated. I uses epoxy paint on heavily used surfaces (like trim saw tables and the inside of cabochon machines). I check every part, lubricate bearings etc., and replace parts as necessary. I update components that are worn or out of date, and occasionally tweak the machines so they perform better than they did out of the factory. All machines come with working, safe motors and I always update the electrical components to make them safe and reliable. If they need a cord I usually chuck the original and make a new one. Old, underpowered motors and old, ungrounded, undersized cords are a fire waiting to happen and go straight into the trash can. If your motor is in good shape I test it and if it isn't safe or will die in a short time I will replace them with new or used motors in good condition. If you need any supplies to run the machines or they require additional setup, I tell you that and give recommendations. I don't leave it up to you to guess like the online sellers. I price the restoration work fairly, factoring out the value of a machine in the condition that you bring it to me. Note that this has nothing to do with the price you paid for it, I usually know what fair value for unrestored machines is, if not I can research them.

You can pay through a Paypal invoice, cash, money order, cashier's check (no bank checks sorry), I can invoice you through Paypal and you can pay on your phone. I can't take a credit/debit card here (Paypal nuked that just to force the small fry into expensive selling platforms).

If you are not intending to buy any equipment, or have any equipment restored, please don't ask questions about anything listed on this page, your saw, your buddy's saw, any other lapidary equipment, etc. I simply don't have the time to answer questions about someone else's equipment so I will NOT respond! (yeah I know someone ignores this at least once a week)

EXAMPLE RESTORATIONS

Slab Saws

Frantom 24" Slab Saw

Highland Park 20" Slab Saw

Highland Park 24" Slab Saw (this one is mine :D)

Highland Park 20" Slab Saw (this one was so beautiful I kept it!)

Hillquist 16" Slab Saw

18" Belmont Slab Saw

16" Highland Park Slab Saw

16" Royal Slab Saw

18" Frantom Slab Saw

Ideal 24" Slab Saw (I didn't do much to this one, it was for me but I bought it in horrible shape)

Highland Park 18" Slab Saw (This was mine for 10 years until I found the 20" above!)

Lortone LS-14 Drop Saw

Lortone LS-18 Slab Saw

Lortone PF-10 Drop Saw

Trim Saws

Sears 10" Trim Saw

Beacon Star TS-10 10" Trim Saw

Rock's Texas 6" Trim Saw

Highland Park 8" Trim Saw

Lortone 8" Trim saw

Highland Park 6" Trim Saw

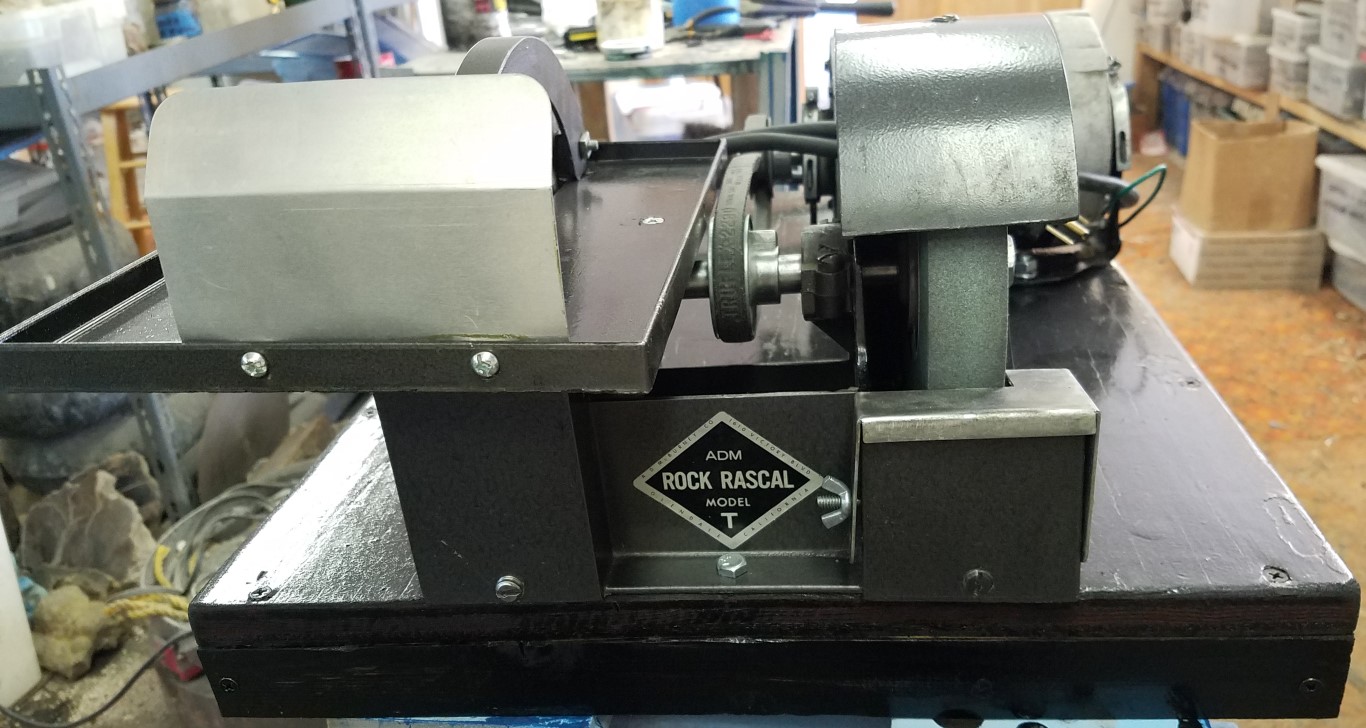

Rock Rascal 6" Trim Saw

Cabochon Machines

Roy's Vertical 6" Cabochon Machine

These 4 wheel are really cool and rare. If you find one jump on it!

.JPG)

Diamond Pacific Genie 6" Cabochon Machine

Lortone 6 Inch 6 Wheel Cabochon Machine

Lortone Max Pro 8C 8" Cabochon Machine

8" Star Diamond GP-8 Four Drum Cabochon Machine

.jpg)

6" Star Diamond GP-6 Cabochon Machine

Covington 8 inch Cabochon Machine

6" Star Diamond GP-6 Cabochon Machine

8" Star Diamond Super GP-8 Cabochon Machine

Fulmer's 8" Cabochon Machine

.jpg)

Ringleader 6" Cabochon Machine

.jpg)

Lortone 6"Arbor

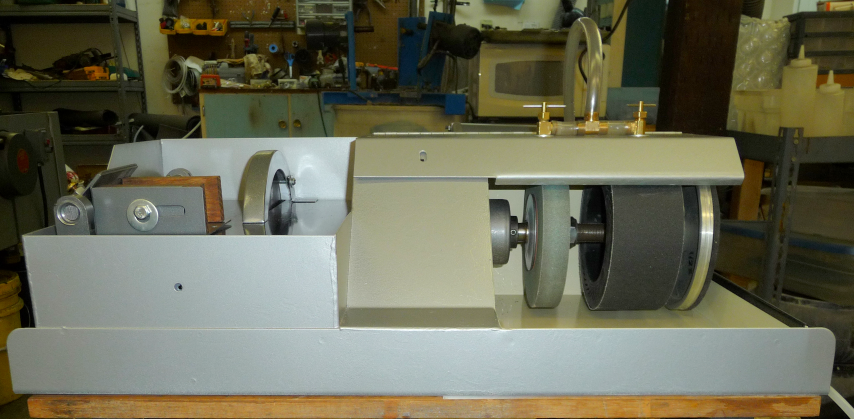

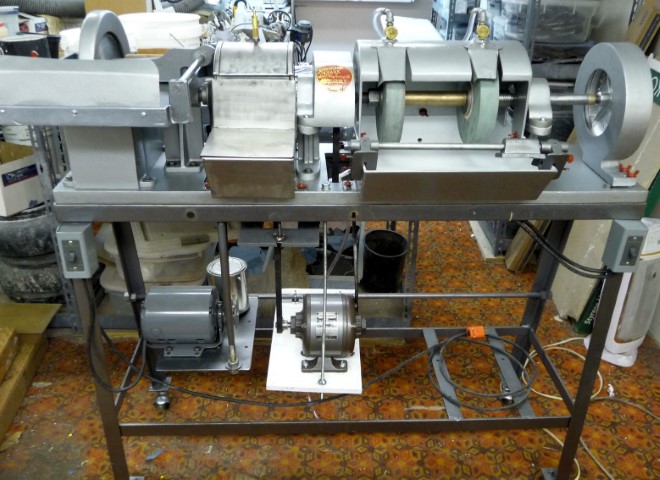

Combination Machines

Highland Park B-20 Belt Sander / Polisher Combo

Lortone LUX-6 6" Trim saw and arbor combo

Highland Park 8" Combination trim saw & grinder

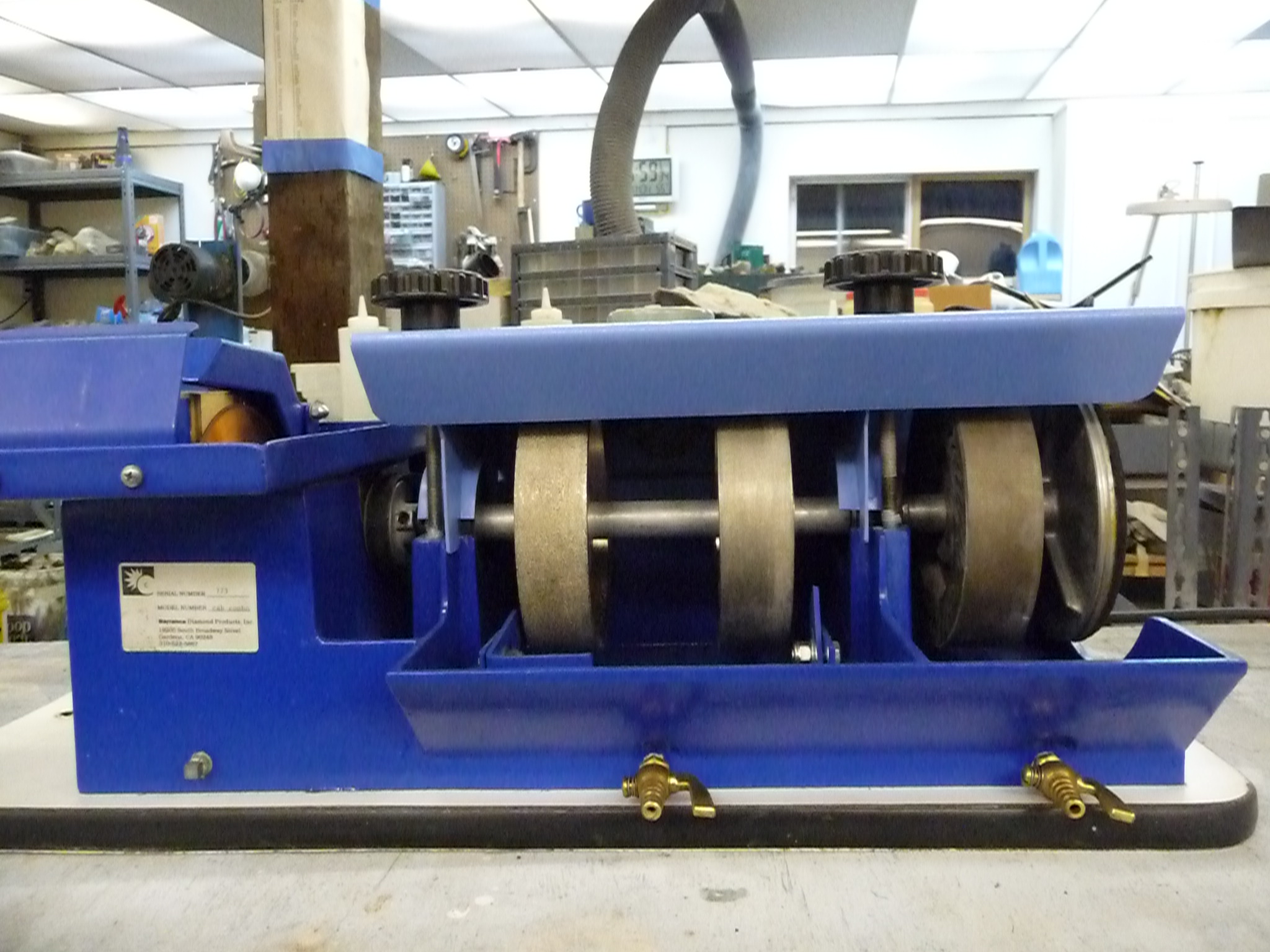

Barranca 8" Combination Machine

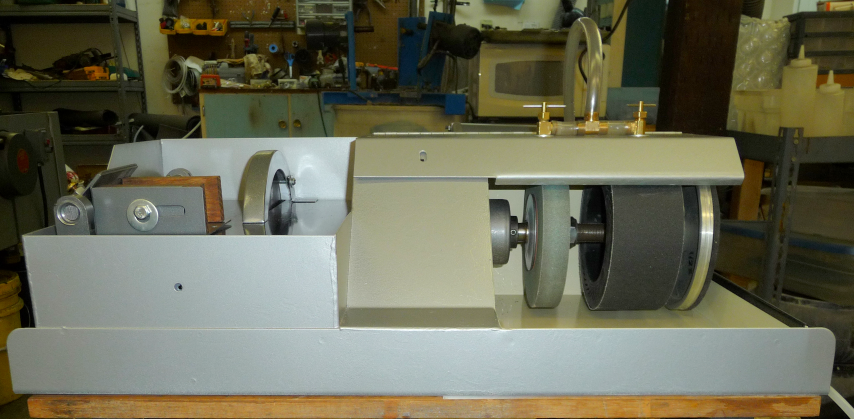

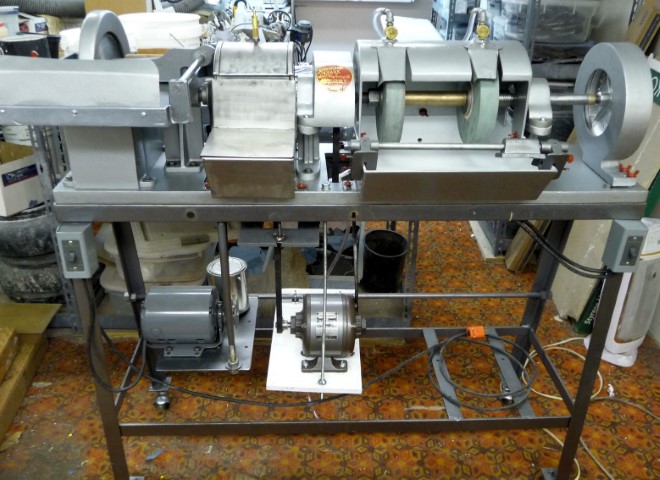

Highland Park All-In-One Combination Machine

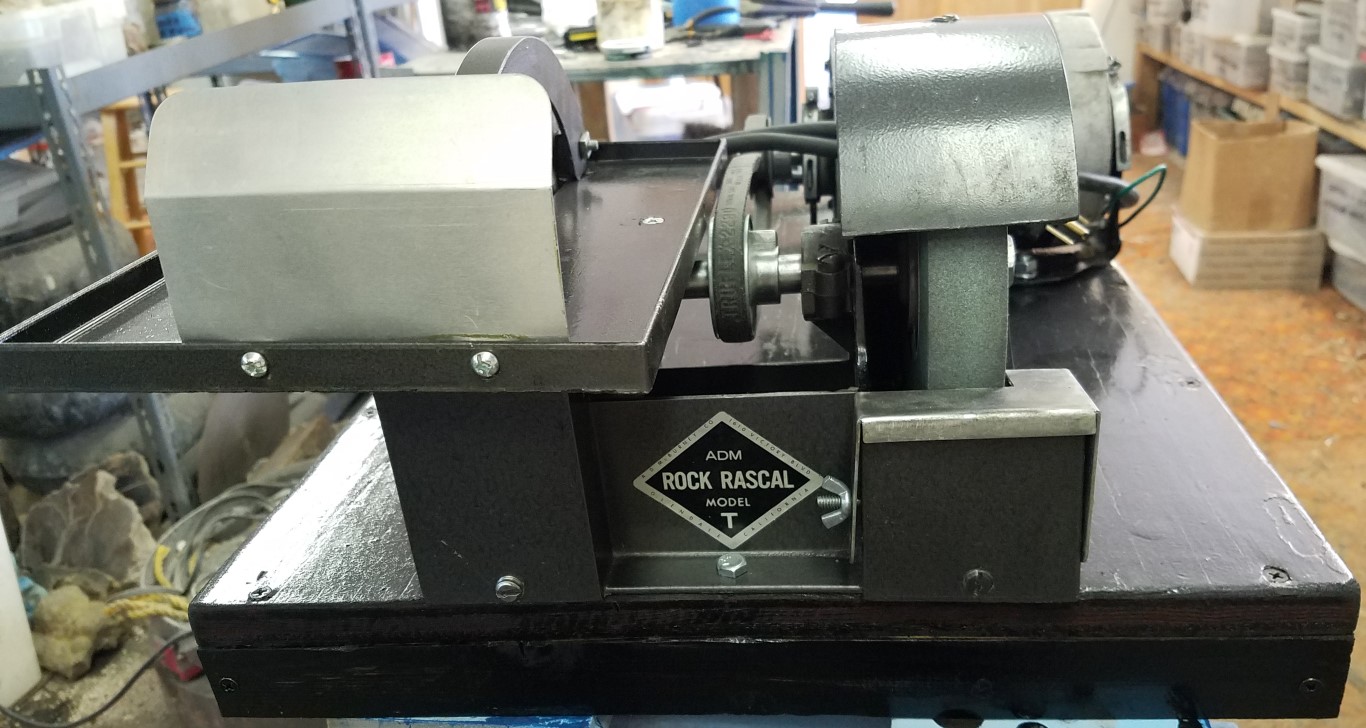

Rock Rascal Model T Combination trim saw & grinder

Lortone LUX-6 6 inch Combination lapidary arbor & trim saw

Highland Park B-12 Combination Cabochon, Polishing & Trim Saw

Lortone Combination Sanding & Buffer Machine

Polishing/Buffing Wheels

Sphere Machines

Scott 2 Head Sphere Machine

Richardson 3 Head Sphere Machine

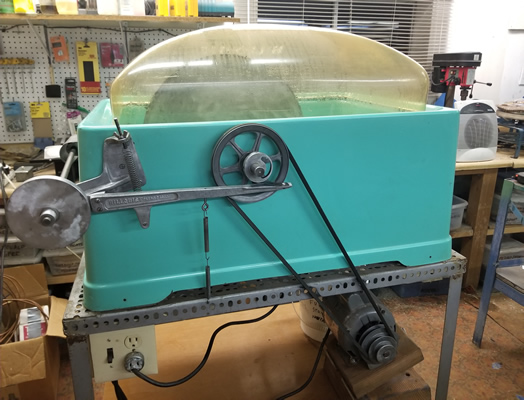

Vibratory Flat Laps

Diamond Pacific 18" vibratory lap

Lortone 15" Vibratory Lap

Lortone 20" Vibratory Laps

Lortone 12" Vibratory Lap

Craftsman 12" Vibratory Lap

Sanders

.jpg)

Covington Mounted Wet Belt Sander

.jpg)

.jpg)

7" High Speed High Overhead sanders

Highland Park Wet Belt Sander

Rock Tumblers

Burr King 40 pound Tumbler

Lortone 2 Barrel Tumbler

.jpg)

Custom 12 Pound Tumblers

Viking Tumbler

Lortone 12 lb. Tumbler

Flat Laps

.jpg)

Craftsman Flat Lap

Copyright © 1997 - 2024

Tim Fisher

Users may download this World Wide Web page

for

personal use only. Unauthorized copying or distribution of this page or

any

of its contents without the express permission of the author is

expressly

forbidden.

![]()

![]()

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

![]()

OreRockOn Rock Collecting Locations Guide

OreRockOn Rock Collecting Locations Guide Lapidary Materials, Faceting Rough, Fossils, and More for Sale

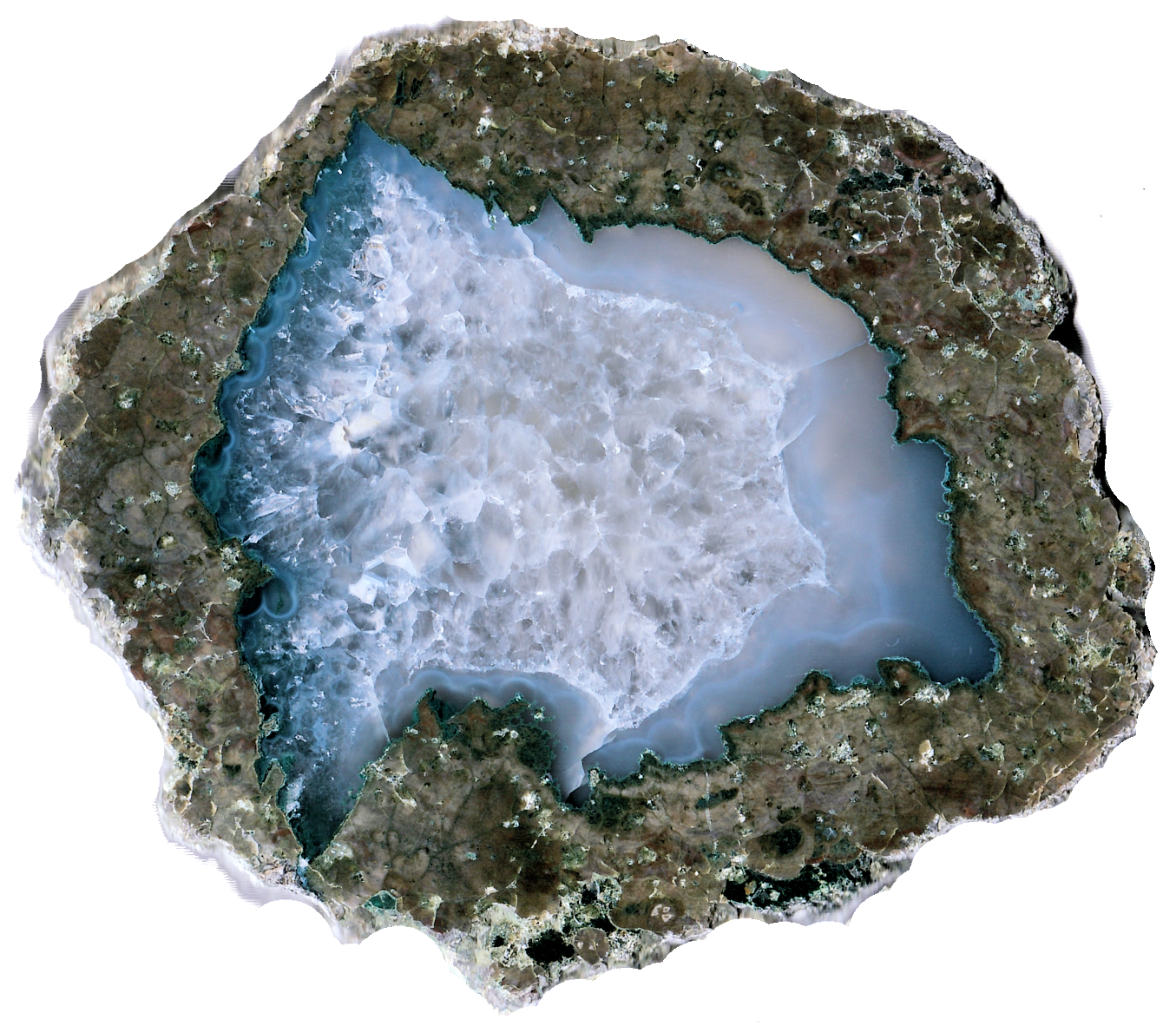

Lapidary Materials, Faceting Rough, Fossils, and More for Sale !ONE TIME ONLY SPECIAL! HOLLEY BLUE Agate For Sale!

!ONE TIME ONLY SPECIAL! HOLLEY BLUE Agate For Sale! Lapidary Equipment for Sale

Lapidary Equipment for Sale Lapidary Arts Instruction Classes

Lapidary Arts Instruction Classes

Rock Cutting and Polishing Services

Rock Cutting and Polishing Services Polished Agates for Sale

Polished Agates for Sale Polished Thundereggs for Sale

Polished Thundereggs for Sale Faceted Gemstones for sale

Faceted Gemstones for sale Cabochons for Sale

Cabochons for Sale Rock Crystal Geodes for Sale

Rock Crystal Geodes for Sale Rock Display Stands for Sale

Rock Display Stands for Sale Rock & Lapidary Bookstore

Rock & Lapidary Bookstore Back to

Ore-Rock-On!

Back to

Ore-Rock-On!