For sale NOW! |

|

7" dry overhead sander sanding disks |

99.99% pure cerium oxide polishing powder |

Trim & Slab Saw oak wood vise inserts |

|

COMING SOON! Contact Me Here if you are interested!(Don't be surprised if I don't answer your message if it doesn't have anything to do with anything currently listed for sale on this page, asking about parts, how to fix a machine, yadda yadda. I won't, I don't have time to answer every question.) |

|

(Click one to go directly there)

Contact me at the link above. It must have all the parts, not look like it was hauled out of a dumpster, and be within reasonable driving distance of Portland OR (I can also meet you halfway). Rusted, no motor, no blade, no wheels are OK. Good, in focus, well lit photos are required. I can't pay Craigslist or Ebay prices so keep that in mind.

I occasionally list equipment for others on this page, and I can sell yours for you (I get a LOT of traffic on this page, and eventually sell everything I list). The arrangements are:

Used and in WORKING condition. As in you KNOW it works as intended. Not completely roached (rusted through, bent, smashed with a sledgehammer, seized bearings, parts missing, ancient rusted motor, iffy wiring). No motor or belt is OK but I'll scream that it's the buyer's responsibility to get them. And if it has a trashed motor or belt then remove it, electrical hazards can be deadly! I'll write a description to highlight the features and any minor work needed. If a buyer says it has problems or doesn't work properly it's your responsibility to work it out with them.

Good, in focus, well lit photos are required, at a minimum from all sides and the top. A clear photo of the inside of slab saws. I'll write a description to highlight the features and any minor work if needed. I can dress up photos (fix lighting, get rid of minor blurring, crop them to just the piece, etc.), but they have to be usable.

It's yours, in your possesion, available to be seen in person, or ready to ship. You ship if necessary, and collect the shipping charges yourself. I'll put your ZIP code in the listing in case someone is close enough to pick it up from you. The point of contact will be me, I'll direct them to you if they have questions about it.

We'll work out a selling price, it won't be sky high but a fair price for the piece. After 24 years selling I pretty much know what people will pay for a piece. I want it to sell, not sit on the page for a year. My fee will be 20% of the selling price, after any fees I incur (namely Paypal which takes a cut of every transaction). I'll provide proof of the sale. I'll pass the remainder on to you (again preferrably through Paypal).

If this sounds like a lot of requirements that's because it is. If any of it isn't acceptable to you then move along :)

If it doesn't sounds like too many requirements to you then CONTACT ME HERE! (Don't be surprised if I don't answer your message if it doesn't have anything to do with anything currently listed for sale on this page, asking about parts, how to fix a machine, yadda yadda. I won't.)

I can occasionally find equipment that I can refurbish, at a reasonable price so I don't have to charge more than I normally would. I won't sell any machine that has not gone through a full restoration/refurbishing. So if you're looking for something in particular we may be able to work something out. CONTACT ME HERE with some basic info, what type of machine are you looking for, what size, how many wheels, etc. (Don't be surprised if I don't answer your message if it is asking about parts, how to fix a machine, yadda yadda. I won't. I know I keep saying this. People keep ignoring it. At least once a week.)

My equipment usually sells FAST so if it says SOLD, it means SOLD. I won't answer emails inquiring about equipment that says SOLD. Check back often for more listings. If you are not intending to buy any equipment from me, please don't ask questions about anything listed on this page, your saw, your buddy's saw, any other lapidary equipment, etc. I simply don't have the time to answer questions about someone else's equipment. That's what email lists are for (hint: Google "rockhounds email list"). That's also what Facebook is for! That's also what rock & gem clubs are for - join your local club! You can pay through the Paypal cart buttons on the page, money order, or cashier's check, and if you pick up your equipment here at the shop I can accept credit and debit cards (usually, apparently it depends on the position of the planets in the sky), cash, money orders, and cashier's checks. S&H & insurance not included. Will ship some items via USPS Priority Mail (if it fits in a flat rate box) larger items via USPS standard mail, or you can come get it or I'll meet you within an hour of Portland (strongly preferred!). I am in Oregon City, Oregon 97045.

If you've recently visited this page, be aware that your browser may have cached the images and although all browsers are supposed to catch new images and reload them, sometimes they don't. So hit the refresh button below just in case to make sure you have the latest pics.

For those of you who are looking for something specific in my for sale pages, such as when I list refurbished equipment, I might have a solution for you. You may want to try this: https://www.changedetection.com, I think all you do is sign up and enter the address of the page, for example if you are looking for equipment enter http://orerockon.com/equipment_for_sale.html, and they should send you an email when I add something. BUT, it probably will send you a notice when I change one letter of one sentence on the page, so you might get annoyed by it at some point. It's a great way to track when I list new polished items or refurbished equipment, since I typically don't change anything until something sells and/or I add items, and equipment, which I never change unless I add new pieces or change the status to "sold" as they sell.

ALL OF YOUR QUESTIONS ARE ANSWERED HERE. I will not, under any circumstances, ship anything international. The rates are now ridiculous as of the huge recent price increase, and I've had enough of boxes being smashed up or going missing on the receiving end. If you aren't a US citizen and you can give me a US address to ship to that's OK. By ordering from this site you are agreeing to all the stated policies on the linked page.

For years I had been using a 5 lb. bag of true "optical grade" cerium oxide polish for all my lapidary work. It produced far superior results to the typical lapidary polishes for me. (Not to toot my own horn but I frequently get comments on how amazing my polish is :). When I ran out a couple years ago and went to find some more I saw a lot on Amazon and lapidary supply websites advertized as "Optical Grade" BUT it was so cheap it got me suspicious. To make it easy for you, low grade cerium oxide is tan (medium grades) to reddish (very low grade) in color. It works great for tumbling, but I refuse to use it for my lapidary work where I demand as close to a "liquid" polish as is humanly possible. BTW I don't like to keep secrets so if you are interested I can give you some tips on what to use and how to work with it. Low grade cerium is comparatively cheap, you can get it in bulk quantity for $25/lb. You can pay way too much to dealers and especially the Amazon and Ebay ripoff sellers. The cheap white powders being passed off as "optical grade cerium oxide" on Amazon, Ebay, etc., according to a silicon chip industry source I contacted (they rely on the real deal to polish the silicon wafers), are actually aluminum oxide (maybe with some cerium mixed in), which gives decent results for tumblers but isn't any better than low grade cerium for slabs, cabs, and halves. It's dirt cheap in bulk quantity, and therefore the sellers are making a couple thousand percent profit on a few ounces of it by lying and passing it off as cerium. My source told me that true optical grade, used by telescope, precision optics, military suppliers, and the silicon chip industries, is over 99% pure cerium oxideby definition. And to boot the particle size matters depending on the material being polished, so all grades are not equal. He suggested an optimal particle size for quartz and so I bought in bulk (becase I had to LOL).

This is 99.90% pure cerium oxide powder, it's the "real deal". If you can find it at all this is a lot less than you'll pay for an ounce. If you use it correctly a little bit goes a very long way. The first 1/2 lb. bag I bought from a trusted source lasted me a year and I polish at least a couple hundred pieces a year, from cabochons to spheres to 100 pound chunks of petrified wood (yikes!).

Genuine optical grade (99.90% Pure) Cerium Oxide Polish - $4.00/ounce (enter the number of ounces in the box that pops up) ![]()

If you have an overhead sander you know how expensive high quality disks are. Generic disks wear out FAST and can actually tear apart and become a huge hazard until you can shut the machine down. Most of my disks are resin bonded to a waterproof polyester backing that is impossible to tear. SOME are paper backed but still hold up (I can't find them in resin bond for less than ripoff prices). I have tried umpteen brands and have settled on the ones that work! The silicon carbide grit itself is resin bonded (the disk is called resin-resin bonded), not glued on like the cheap disks. Paper backed disks are high quality, unlike the cheapo disks where the grit pulls off the paper after you sand a couple pieces. These last me 20- 40 pieces (and I don't do small rocks). I buy in bulk so I get a big price break over single disks. The typical progression used is 60-100-220-400-polish. 36/40 grit is used for pieces that have larger saw marks (if you need it then you need to figure out what is wrong with your saw!). In general the coarser the grit the longer it lasts. IF you can even find them sold individually they are way overpriced! At just over $1.00 each these are a bargain! Tip: to get a really flat surface cut eight 3/4" slits evenly around the hole; most come with 4 slits so make 4 more in between them. These also work with a bull wheel type sander that has a screw on locknut.

Dry Sanding Disks |

||

Grit |

Per disk |

Available? |

| 36/40 | YES |

|

| 60 | $1.30 |

YES |

| 100 | $1.20 |

YES |

| 220 | $1.10 |

YES |

| 400 | $1.00 |

YES |

| Full Kit | $12.40 |

YES |

Full Kit = (1) 36/40 (I have both and there's no perceptible difference between them), (1) 60, (2) 100, (3) 220, (4) 400 disks. This is typically what you'll need, the finer grit disks wear faster. The prices on these have blown up since the catastrophe hit; the 60 grit 100 pack is now over $200! But I'm keeping them low as long as my supply holds out!

I have been making vise inserts for myself and for saws that I sell/refurbish for a couple decades. I've decided to offer them for sale because I think it's a shame when I hear or read about people having trouble with gripping the rock tight enough that it doesn't shift or worse pop out of the vise in the middle of a cut. That can mean catastrophe, like a bent or chipped blade that can't be repaired without a lot of skill. Most that come from the manufacturers are masonite or worse yet plywood. They are WAY TOO SOFT to securely grip a rock, while the wood does compress a bit to make the grip more secure, it keeps on giving under pressure, so if the blade is dull or the cut is going sideways they can just lose their grip altogether! The wisest lapidaries all use much harder wood that deforms but doesn't split, and from my experiments oak is the best, relatively affordable wood. I say relatively because the last piece of oak board that I bought was almost $19! That's exactly why I'm making my own now, I have a good supply of oak and the means to mill and plane it. Besides, most manufacturers don't even sell them, and the ones that do use garbage wood.

This is an insert that one manufacturer is currently offering. It's garbage plywood and the thin hardwood laminate will probably start to split on the first cut!

This is a pair of my inserts (solid oak, and they aren't cut long because I modified this vise to advance all the way to the blade):

Inserts are priced at 50 cents per SQUARE INCH. For example if you need two 4 by 4 inch inserts, the price is 4" x 4" x 2 inserts x $0.50 = $16.00.

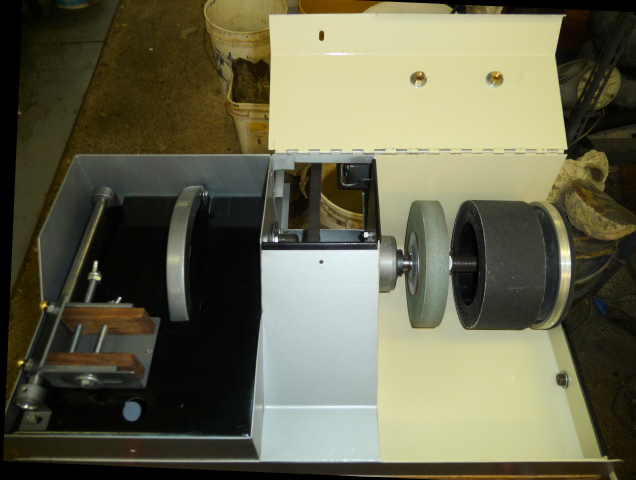

Refurbished Lortone Model LUX-6 combination grinder and trim saw for sale! This 6-inch all-in-one lapidary trim saw and lapidary arbor is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, stripped, painted, epoxy coated trim saw table and inside of the grinder for extra durability. Mounted on an overbuilt rock steady base. The trim saw has vise that travels on a rail, for slicing (small) rough. It is not meant to cut slabs. It's most useful for trimming slabs to get them ready to make cabochons (conveniently located within a foot of the saw lol). It could be converted to a weight feed system with a couple bucks worth of parts. The blade is a used 5 1/2" Felker diamond blade in good condition, but it's made for a 6" blade. The saw is meant to use water, not oil. Lortone went cheap and didn't put a drain on it, so I added a drain and hose for you :) Drain it every time you're done and use an anti-rust additive such as Lube Cool. The arbor has a drain & hose, 6" general purpose silicon carbide wheel (I believe there are 100 grit), and a 6" expando drum for sanding belts (doesn't look like it's been used). The shaft is designed so you can put a disk on the right end for sanding/polishing etc. Kingsley North has the right parts, I think a hook and loop disk, with diamond sanding and diamond or leather polishing pad would work out great. NEW 1/3 horsepower motor, new belt and switch. Water supply system with 2 valves, I'll show you the bucket I made for a water supply. All you need is to drill out a container, glue the tubing to it or screw a couple dollar fitting in (my preference).

Pickup here Oregon City, OR or I can meet you within an hour driving distance of the Portland area

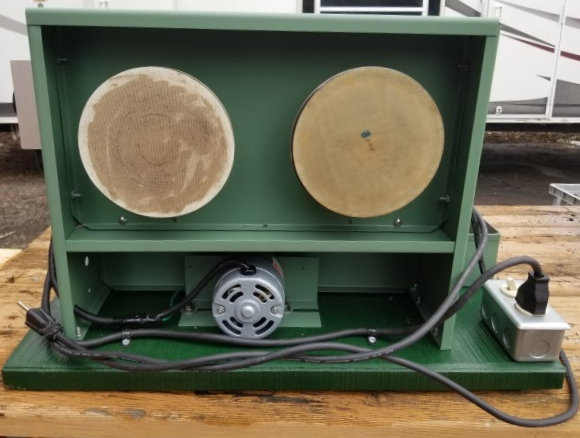

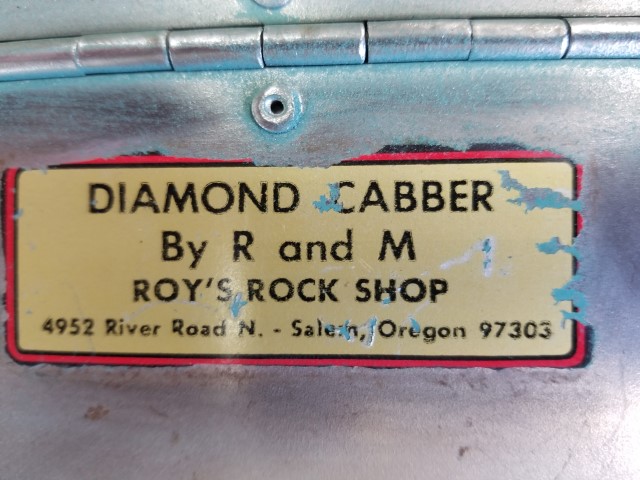

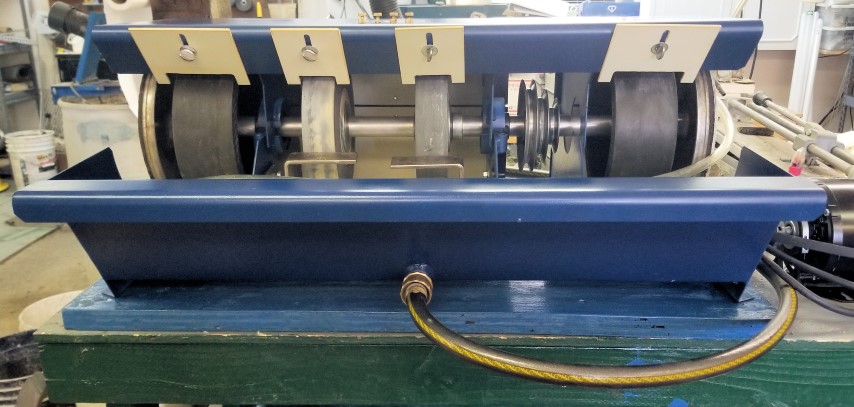

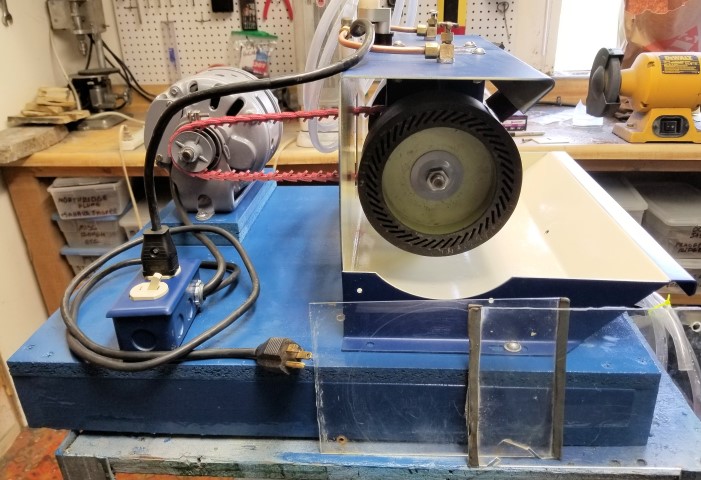

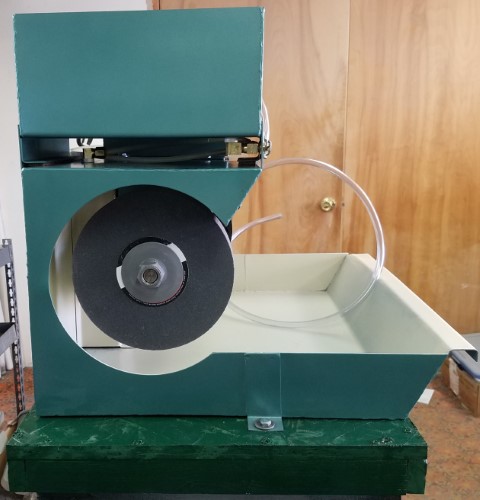

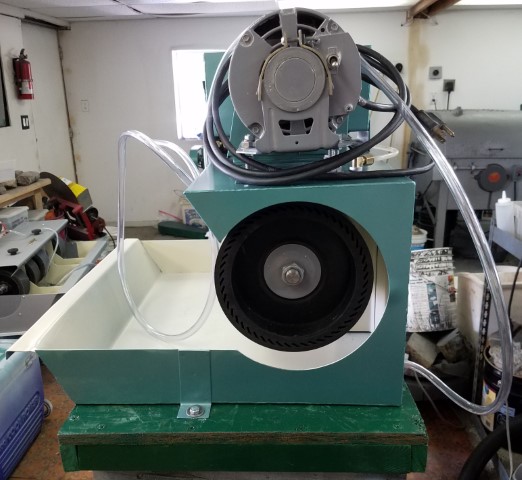

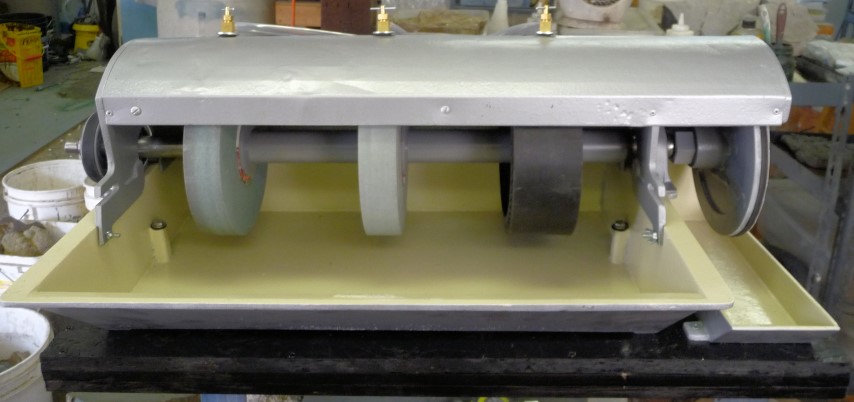

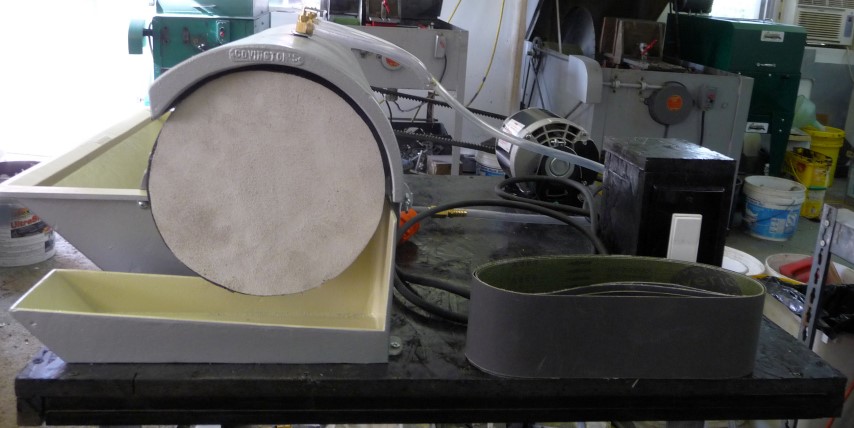

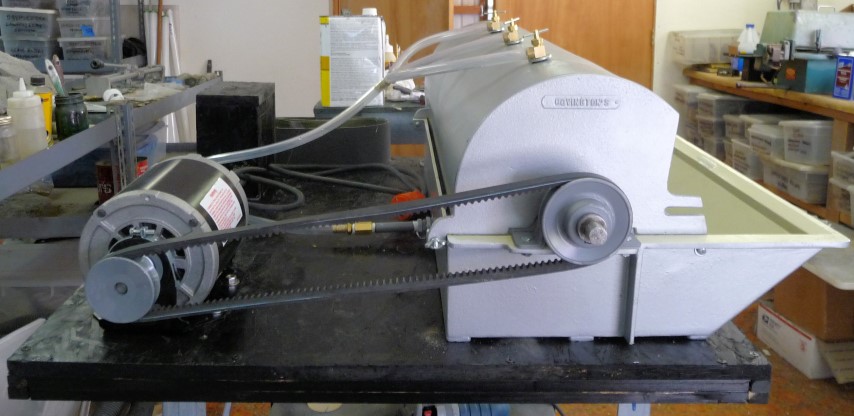

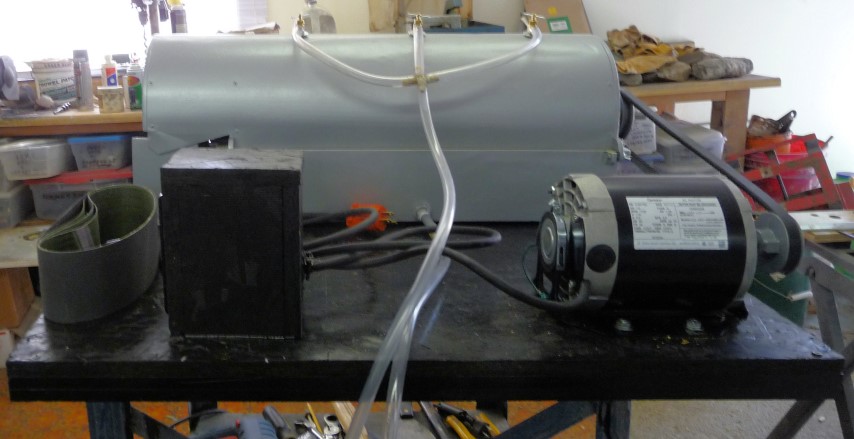

Roy's Rock Shop 4 disk vertical cabochon machine for sale! This is an ingenius machine manufactured by a long gone Salem, Oregon rock shop. They made these and other machines in multiple configurations, I have seen a trim saw made with many of the same parts! I know of a few lapidaries that use this machine exclusively for making cabochons, some for decades. It has 2 disks for silicon carbide or diamond sanding disks in the front that stick onto the pads with disk feathering or other contact cement, and 2 canvas pad disks in the back for diamond paste. Not shown are 2 other grit diamond disks and a felt polishing disk. I'll throw in all the goodies that came with it, contact cement, polishing powder, diamond paste, and a bunch more supplies. The front side is wet (the pump sits in the reservoir as in the photo) and you can control the amount of water to each disk with the valves. The back side for diamond paste and polishing is dry, you use diamond extender spray to keep the paste from drying out and a spray bottle for the polishing pad. There was nothing to be adjusted or repaired except the motor was a little tired. I replaced it with a new variable speed motor up to 10,000 RPM motor (you will never need to run it at full speed). I added a switched outlet so the pump and motor are controlled separately.

Pickup here Oregon City, OR or I can meet you within an hour driving distance of the Portland area

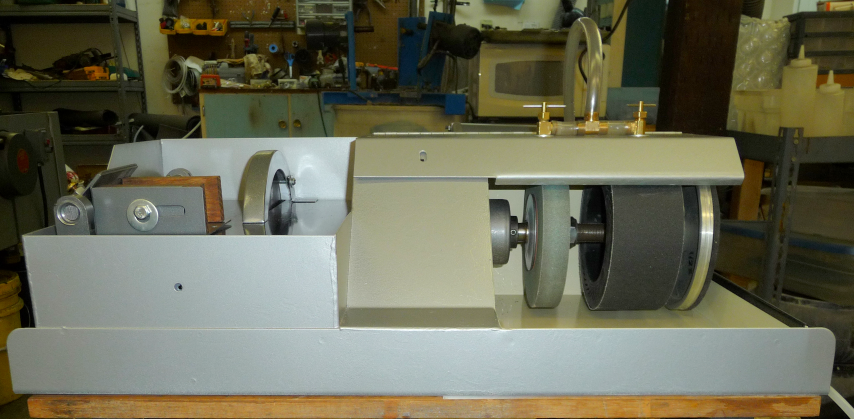

As you can see this beauty is decked out with everything you need to go from a chunk of rock to a beautiful cabochon! It was in great shape, I cleaned it up, changed a few things around and it purrs like a kitten. Mounted on a rock solid base which needs to be screwed or bolted to your work surface. New motor and belt that you have to mount (I have no idea how much room you will have). You can make a sliding mount to change speeds (it has a triple pulley) but I would leave it right where it's at, I set it at 800 RPM which is where these arbors perform best. Add a bucket to supply water, I'll show you how I do it. 2 expando drums in great shape take silicon carbide or diamond belts, 2 silicon carbide grinding wheels in great shape, and 2 disks for polishing and whatever else you can dream up :) One disk is covered with a new leather polishing pad, and I'll throw in an assortment of belts for the drums and optical cerium polish for the pad to get you started.

Refurbished Highland Park model E-10 combination grinder and trim saw for sale! This 8-inch all-in-one lapidary trim saw and lapidary arbor is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, stripped, painted, epoxy coated trim saw table and inside of the grinder for extra durability. The trim saw has a plastic coated wire weight feed, you supply the weight or I have a couple 2 pound (barbel weights?) that came with it. The blade is used in very good condition. The grinder has 2 silicon carbide wheels, coarse and medium grit. The shaft is designed so you can put a disk on the right end for sanding/polishing etc. Kingsley North has the right parts, I think a hook and loop disk, with diamond sanding and diamond or leather polishing pad would work out great. There is a tiny chip out of the edge of the medium wheel that won't effect the performance. Great condition used 3/4 horsepower motor, belt and switch. The bearings are great and it runs smooth and quiet. It has a 3 position pulley so you can run it from 1035 to 1725 RPMs. These older grinders do a better job at the slow speed, the saw runs best at the high speed. Water supply system with 2 valves. It would be fairly straightforward to drill another hole in the hood, take out the center part of the spacers (it's the right width for another wheel so I think someone had that in mind), and run another wheel in the center. All you need is to drill out a container, glue the tubing to it or screw a couple dollar fitting in (my preference). Note that these units drain out the back, so keep that in mind. I'm waiting on a drain hose for the grinder.

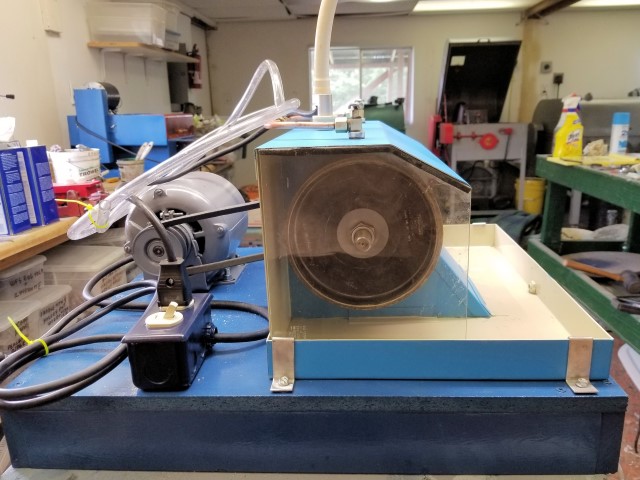

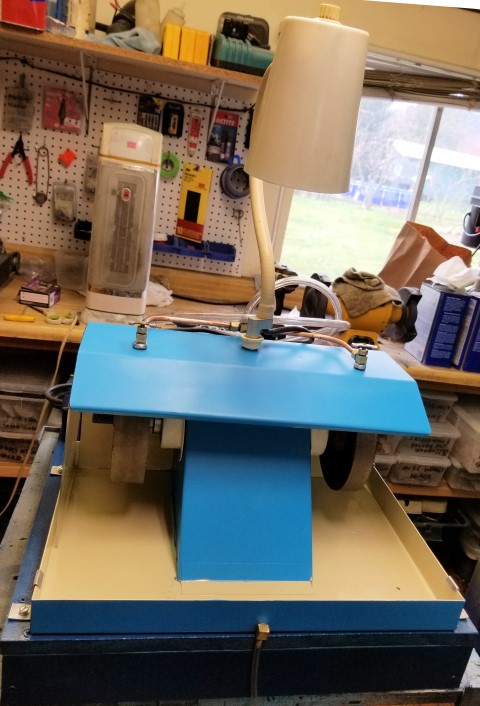

This machine is functionally the same as the Lortone SA-6 below. It was in great shape when I acquired it, so all I did was disassemble it, remove any corrosion, repaint, and added the water supply and drain lines. What's really cool is the owner added a Genie lamp so you get the light where you need it the most. It's directly connected to the outlet so it always has power and you can use it with the machine switched off. Like all of my refurbished machines it is plug & play (you supply the bucket for the water supply since I don't know what your situation is). Has a 1/3 HP motor in great condition, and 2 like-new condition expando drums for silicon carbide or diamond belts (they are available in many grits so you can go from rough shaping to pre-polish). Kingsley North sells them here. New water supply hose and drain. Mounted on a rock solid base. What's nice about these is that you can buy off the shelf disks to screw onto the ends of the shaft. Then you can do the final sanding and polishing on the machine as well. Kingsley North sells the disks here. The 2 homemade Plexiglas side shields screw into the holes in the base. They fit right so I didn't do anything with them. With a little tinkering they would look better. These are little workhorses, and last practically forever if they're well taken care of.

Pickup here Oregon City, OR or I can meet you within an hour driving distance of the Portland area

This machine was in great shape when I acquired it, so all I did was disassemble it, remove any corrosion, repaint, and made a couple improvements. What's really cool is the owner added a Genie lamp so you get the light where you need it the most. It's directly connected to the outlet so it always has power and you can use it with the machine switched off. Like all of my refurbished machines it is plug & play (you supply the bucket for the water supply since I don't know what your situation is). Has a 1/3 HP motor in great condition, and 2 diamond wheels (80 & 180 grit). New water supply hose and drain. Mounted on a rock solid base. What's nice about these is that you can buy off the shelf disks to screw onto the ends of the shaft. Then you can do the final sanding and polishing on the machine as well. Kingsley North sells the disks here. The wheels are top shelf Diamond Pacific, well used, and I honestly don't know if you can get much more out of them so I didn't factor them into the price. New wheels are here and many other lapidary suppliers. The 2 homemade Plexiglas side shields kinda fit right so I didn't do anything with them. With a little padding around the edges they would fit securely, personally I think they're unnecessary, if they were you'd see hundreds of machines with them. These are little workhorses, and last practically forever if they're well taken care of. A junked one of these just sold on Ebay for $350.

Pickup here Oregon City, OR or I can meet you within an hour driving distance of the Portland area

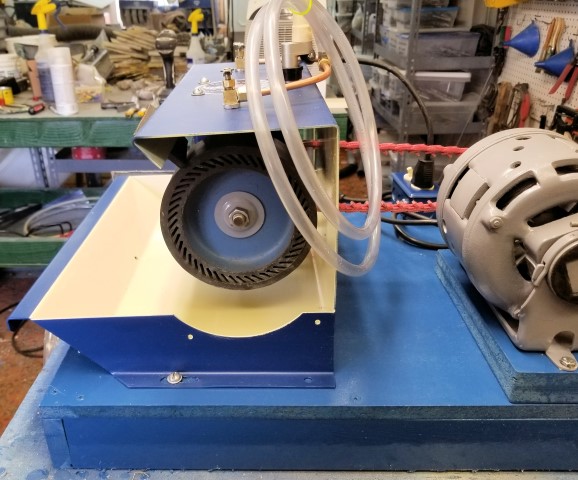

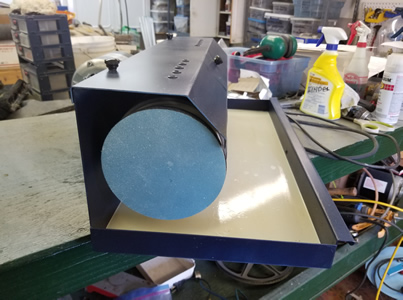

If you've never seen one of these before you don't know what you're missing. If you polish ANYTHING with a flat cut surface this will save you an unbelieveable amount of time and expense over a flat lap. I use mine at least once a week, sometimes for hours on end or until I can't feel my arms anymore. It works like any disk sander, the disk locks on with a nut so it's quick to change. No nasty, hard to remove contact cement is necessary. Just turn it on put the rock up to the disk and sand away. You need to use different grit disks to get it to ready to polish, usually 60-100-220-400-polish. This is pretty much exactly how it was sold, but it has a hand built shield (as in someone with mad woodworking skills)! It has a 3450 RPM switched motor, flexible rubber disk backing plate, a tool to remove the locking nut, and a set of disks to get you started. The shield is an improvement over the original (it captures more dust), and you MUST use an exhaust that fits over the hole in the back of the shield, a Shop Vac has plenty of suction. Breathing in rock dust is no joke! These are $495 new from the manufacturer and they aren't substantially any different than this one. I follow up with polishing on a bull wheel buffer also sold by Richardsons, hands down the fastest and best way to polish just about any rock. If you're interested I may be able to build one for you (for substantially less than the $395 they sell for), I already have most of the parts.

Pickup here Oregon City, OR or I can meet you in the Portland area

Refurbished Lortone 6 inch 6 diamond wheel cabochon machine for sale! This is a real sweetheart, it was practically in mint condition when I picked it up, I just gave it a solid inspection, tear down, paint, and rebuild. Has a new 1/2 HP motor & belt. The 6 wheels are in great shape, 80 and 220 grit hard wheels and 280, 600, 1200 and 3000 soft wheels. The 280 grit soft wheel is a little more worn as would be expected (it's always the first one to go, coming after the 220 grit hard wheel). It has a disk on each side, one canvas for diamond paste and one felt disk for polishing. You can have all the accessories that came with it including disk cement and an assortment of diamond paste.

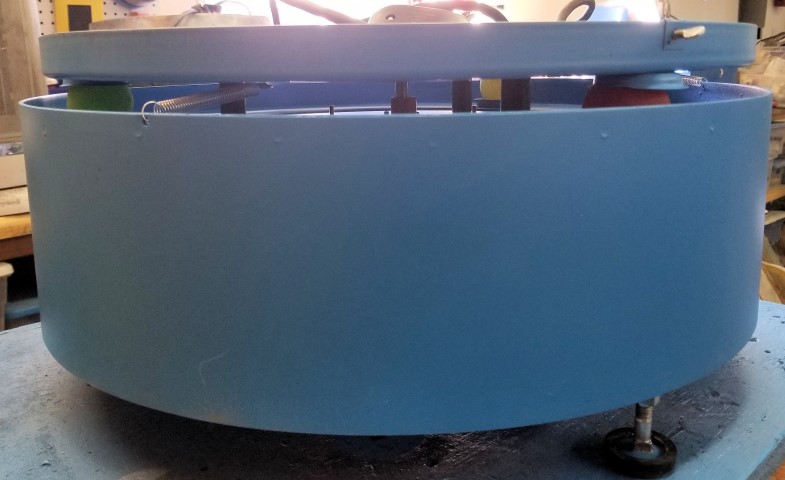

Refurbished Lortone FL-15 15" Vibratory Lap for sale! This 15 inch lapidary vibratory lap machine is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, rust removed, painted, 2 lap pans (grinding and polishing), bumper rings, new motor, ball supports and springs. Runs perfectly. I'll throw in a grit kit, 60/90, 120, 220, and 400. These are going for ridiculous prices used because Lortone stopped producing them in favor of their ultra-expensive oscillating lap. I'm not that greedy so I'm pricing it well under the only used machines I can find (all unrestored machine). Contact me for a video.

Refurbished Lortone FL-20 20" Vibratory Lap for sale! This 20 inch lapidary vibratory lap machine is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, rust removed, painted, 2 lap pans (grinding and polishing), bumper rings, new ball supports and springs (I'm waiting on the original replacement balls, the balls in the photo aren't them). Runs perfectly. I'll throw in a grit kit, 60/90, 120, 220, and 400. These are going for ridiculous prices used because Lortone stopped producing them in favor of their ultra-expensive oscillating lap. I'm not that greedy so I'm pricing it well under the only used machines I can find (all unrestored machine). Contact me for a video.

From Lortone: A proven workhorse the FL-20 vibrates at 1600 times per minute giving consistent and excellent abrasion to your specimen. This comes with 2 each 15" pans, one for grinding and one for polishing. Each pan includes a 3/8 OD polyethylene tube bumper ring. These pans are made of aluminum and the polish pan comes with its own polishing pad. Pans are easily removed for changing or cleaning.

Pickup here Oregon City, OR or I can meet you within an hours drive of the Portland area

.jpg)

.jpg)

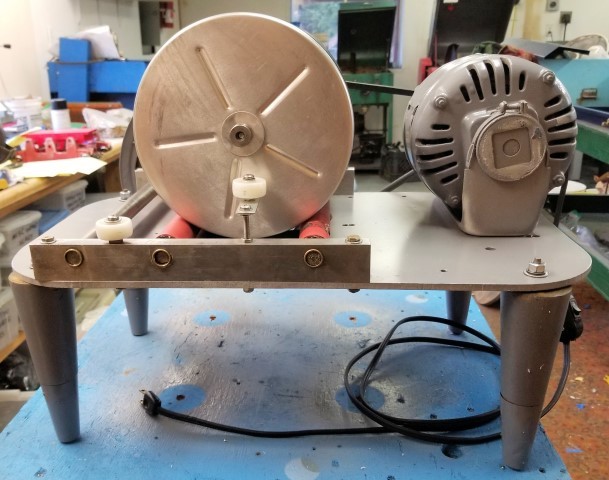

This is a massiely over-engineered home built tumbler. It will probably survive a tornado. Heavy duty alumunum construction, wood legs from what looks like a coffee table haha, used motor in excellent shape, great condition belt and pulleys, 2 pound Lortone Barrel in pristine condition. I added new wiring and an inline switch. I don't know what the extra roller in the front is for, I think they intended to use a smaller barrel too but I don't have any to test it with. Contact me for a video.

Pickup here Oregon City, OR or I can meet you within an hours drive of the Portland area

Click on a photo for the supersize image!

![]()

![]()

![]()

![]()

![]()

![]()

This is a completely restored powerfeed Beacon Star Trim Saw in excellent condition. I've never seen one in such good condition for sale and the lids almost always break or get lost. I have slabbed a lot of rocks on it but I have another 10" saw so one of them has to go. This is an all-aluminum top and arbor shaft so it will never rust. The tank is steel. It has been completely stripped, primed, painted, and clearcoated. Epoxy paint on the table for extra durability. Original lid, good pulleys, belt, overpowered by a NEW 1/3 horsepower motor, good wiring, new drain pipe and new sturdy base, and my thin MK Diamond 303 Professional 10" diamond blade. These are a great blade for saving material as they spin up they get very rigid (I use one for trimming faceting rough). It has a traveling table that slides on a rail and an automatic screw feed that I slowed down from the factory speed to get smoother cuts. It cuts off both the feed screw and motor automatically when it hits the adjustable stop. The vise is aluminum and features my soon to be patented "lift a jaw" system (3 wood blocks) that support the back of the upper jaw so the rock doesn't shoot out partway through the cut. That was an easy to fix defect in the orginal design IMO. One corner of the lid has been repaired (oilproof sealant), I smashed a rock into it years ago (oops!). It can be set up as a weight feed vise in minutes but I have no idea why anybody would do that. You can use oil or water with an anti-rusting additive like Lube Cool or Crystal Cut. The drain is in the front so you can easily empty it after you're done if you're using water. BUT this saw was designed to be used with oil and I for one wouldn't use water in it.

Click on a photo for the supersize image!

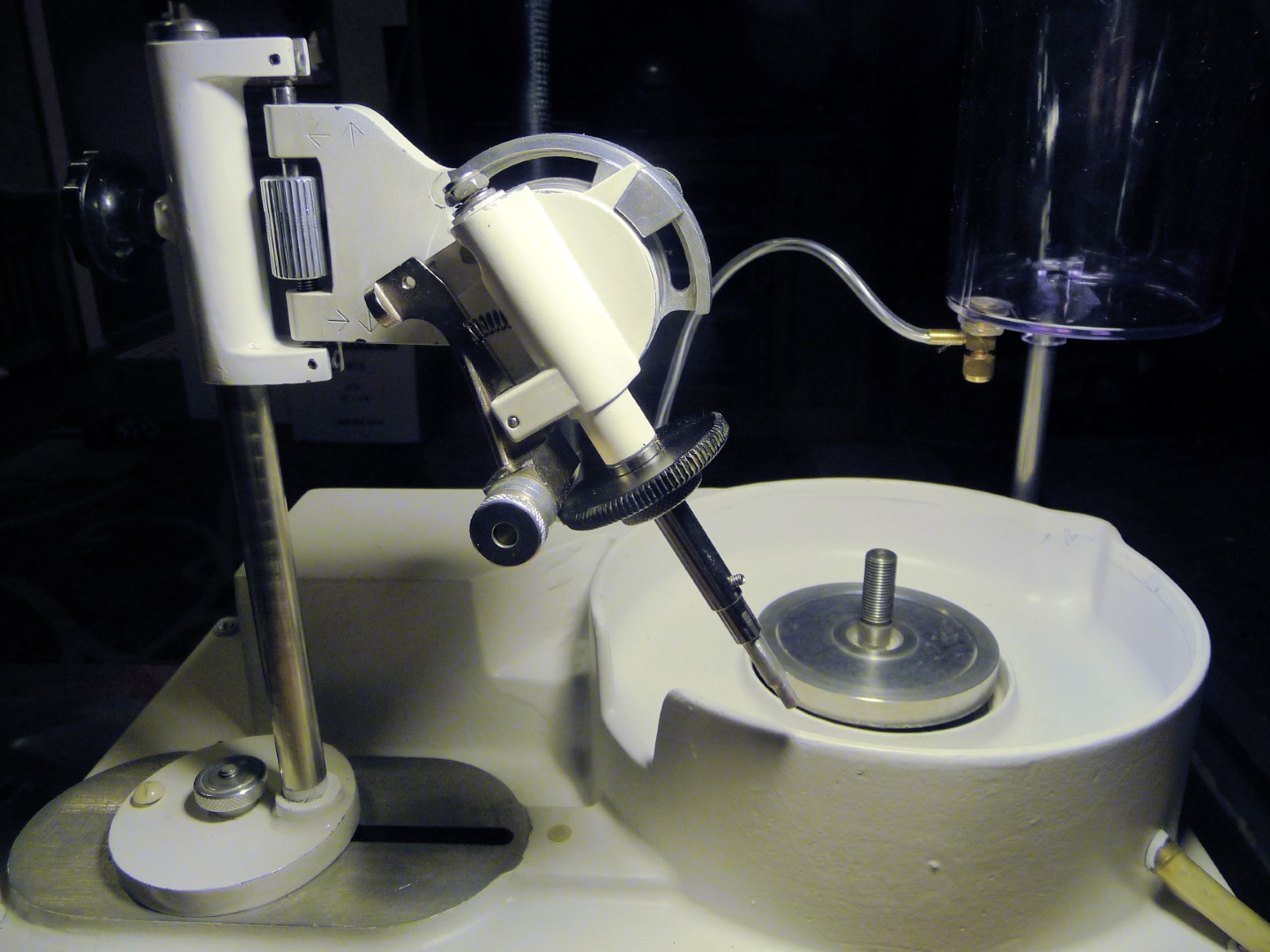

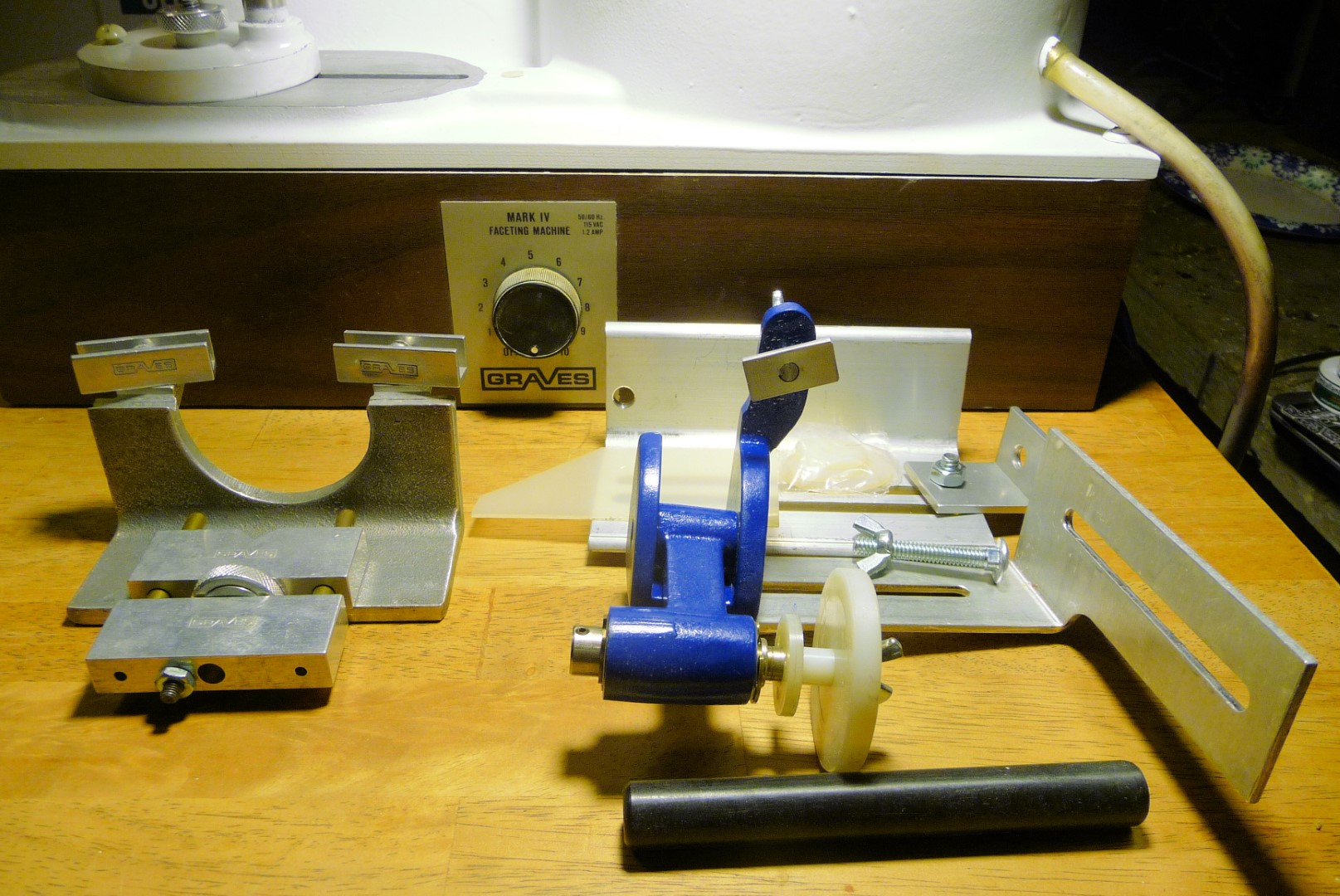

The main machine, brand new water tank upper right. The base has been repainted to match the original. It has a variable speed control and brand new belt.

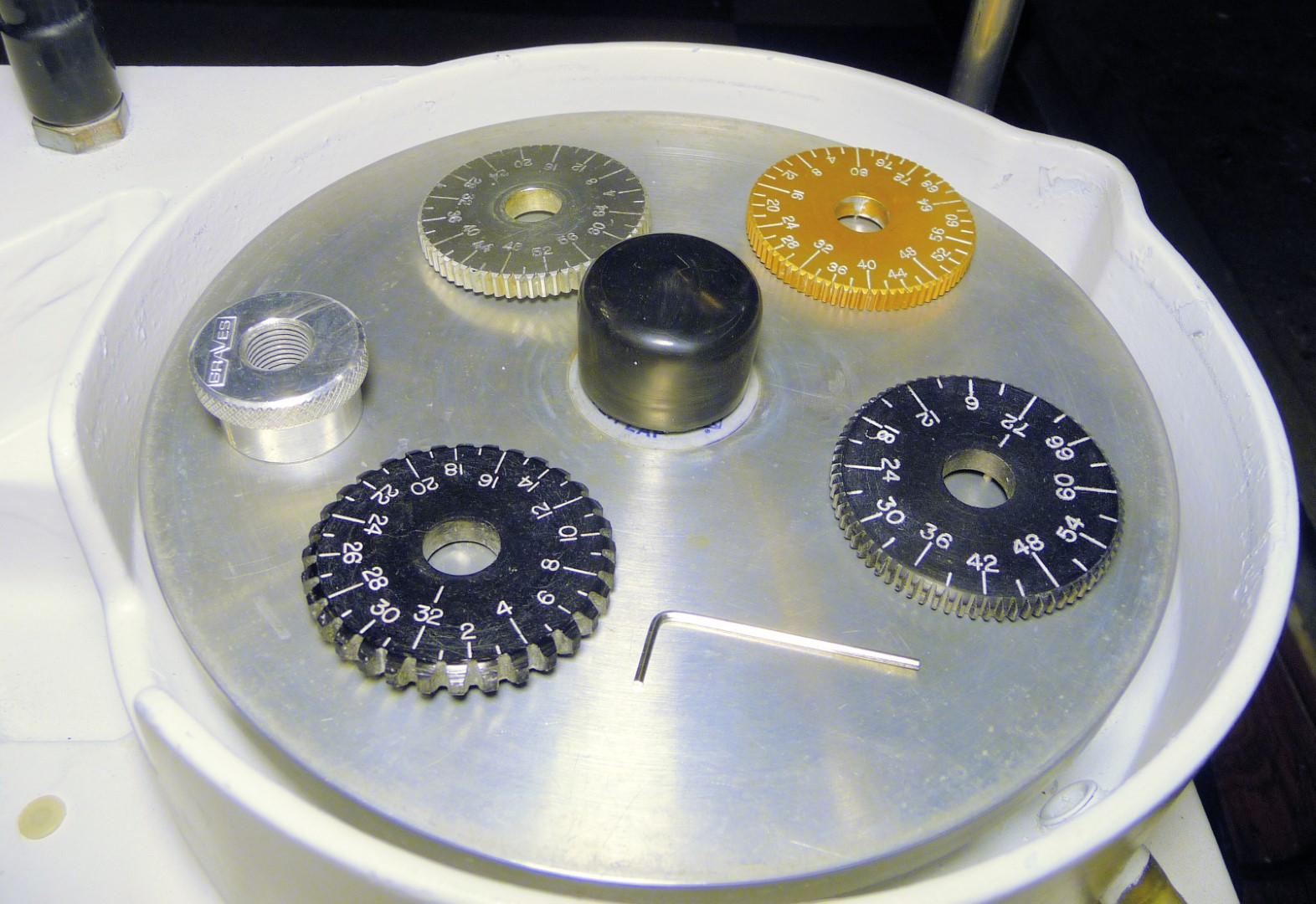

Index plates (minus the 96 which is on the handpiece) - 32, 64, 72, and 80. These are used for designs with a different outline, and you can cut many more designs other than the standard 96 (for 3, 6, 9, 12 sided designs). Also the allen key for the dop holder, the standard lap nut, and a "quickie nut" which goes on with just a twist, makes the laps faster to change. The master lap doesn't come with the machine.

Dop holder and 32 dops, there is one for every occasion and some you'll probably never use. The silver ones are aluminum, the rest are brass from Graves. The table dop isn't from Graves, I don't know what brand it is but it was made for this machine.

Graves transfer tool and preformer kit. The preformed was new in the bag, I took it out but never used it (I facet backwards - girdle last). The black stick is a handle for preforming stones by hand. The original Graves transfer fixture is on the left. The girdling attachment in front of the transfer fixture attaches to the base to allow for rapid preforming before cutting the girdle.

This is a recent Graves Mark IV in excellent condition. I have cut a lot of stones on it. The base has been repainted to match the original. It has a variable speed control and brand new belt. It has the original gooseneck light (permanently attached, not visible in the photos) a new Graves water tank and belt and plenty of accessories. Other than those it's all original, nothing has ever been monkeyed with. I've had it serviced by a technician and it's perfectly aligned. It has the original index plates, 96, 32, 64, 72, and 80. Also a quickie nut which saves time changing laps. Has a Graves transfer fixture, and a new Graves preformer kit that I took out of the plastic but never used. And a girdling attachment that I know how it works but again have never used. The black stick is a handle for hand preforming (again never used). It has 5 index plates - 96 (on the handpiece in the photos), 32, 64, 72, and 80. These are used for designs with a different outline, and you can cut many more designs other than the standard 96 (for 3, 6, 9, 12 sided designs). Also the allen key for the dop holder, the standard lap nut, and a "quickie nut" which goes on with just a twist, it makes the laps faster to change. The master lap doesn't come with the machine. It comes with a dop holder and 32 dops, there is one for every occasion and some you'll probably never use. The silver ones are aluminum, the rest are brass from Graves (as far as I can tell the table dop is not from Graves).

This is an insane price for a tried and true, plug & play faceting machine. It's just taking up space in my shop!

Click on a photo for the supersize image!

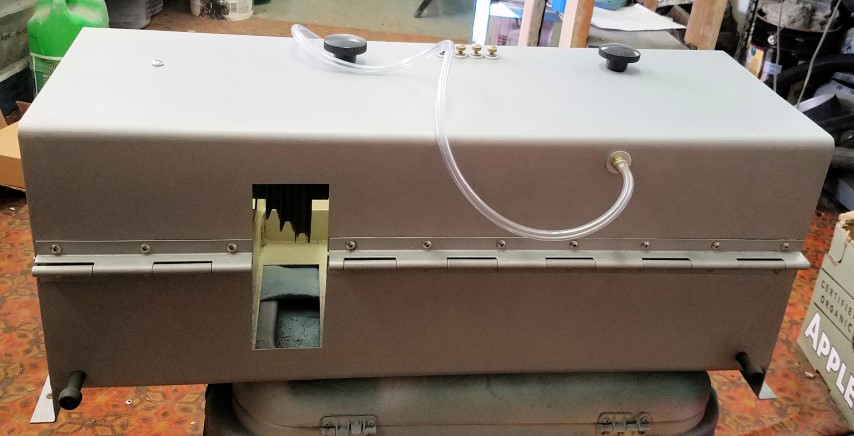

This is a very different type of trim saw than most others. It is designed to precision trim slabs and can cut very thick slabs or small pieces of rough. I already have a trim saw for large faceting rough or I would keep this one, it's perfect for cubing up pieces to fit on the faceting machine or for making marbles. This is an all-aluminum top so it will never rust. The tank is steel. It has been completely stripped, primed, painted, and clearcoated. Epoxy paint on the tables for extra durability. New pulleys, belt, 1/4 horsepower motor, wiring, switch, plug, drain valuve & tubing, sturdy base, and 6 inch Kingsley North diamond blade. I'll throw in the original blade that came new with the machine, it may have some life left in it. The blade shaft is a greased bronze sleeve type and it's so quiet you can barely hear it running. Just add grease through the nipple when you think of it, maybe once a year with light use. It has a traveling table that slides on a rail and a roller bearing so it is perfectly rigid and aligned properly to the blade, and it is fed by hand. Just remember to go slow, I see too many hand fed trim saws that were thrashed by people trying to rush it. There is an aluminum fence that screws into any of 8 different holes and adjusts to any position you can think of. You can use oil or water with an anti-rusting additive like Lube Cool or Crystal Cut. The drain is in the front so you can easily empty it after you're done if you're using water.

This is a completely rebuilt trim saw from a Highland Park trim saw/cabochon/polishing machine. Completely stripped, primed, painted, and clearcoated. New pulleys, belt, 1/4 horsepower motor, wiring, switch, sturdy base, splash shield, bearing, and MK Diamond 301 blade. It has a traveling vise with a weight feed system, just add string and a weight, or feed it by hand. It also has a guide on the opposite side for trimming slabs. You can use oil or water with an anti-rusting additive like Lube Cool or Crystal Cut. The drain is in the front so you can easily empty it after you're done if you're using water.

Refurbished Lortone Max-Pro 8C 8-inch cabochon machine for sale! This 8-inch lapidary cabochon machine is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, stripped, painted, set on a super heavy duty base with the original 1/3 HP motor, NEW 100 grit silicon carbide wheel, NEW Expando-type sanding drum, NEWE 8" screw-on convex foam polishing head with a leather cover, new drain hose, on a heavy duty base. There is space for another polishing or sanding head on the left side. Self-contained water drip system with independent valves. 8 silicon carbide belts for the drum sander to get you started (2 each of 220, 400, 600, 800 grit). Unscrew the polishing head when you're sanding and screw it in to polish with oxide polishing compound. The 2 side shields clip on when you're not using the polishing heads. You can change the drum belts without removing anything.

Pickup here Oregon City OR or I can meet you in the Portland area

Refurbished Star Diamond GP-8 4 drum cabochon machine for sale! This 8-inch lapidary cabochon machine is totally refurbished by me, and ready to run right now! Someone thought of putting 4 drums instead of 2 drums and 2 wheels on this machine and had a genius idea and poor execution. I fixed all that and it runs like a champ. Here's the details: Completely disassembled, stripped, painted, new bearings, a NEW 1/3 HP motor (not pictured) and I can pick out a belt if you know where you will be putting it. Just bolt it to your work bench. The expando-type drums are practically brand new, I don't think they used it much if at all because of the "issues" they left (basically they had no idea how to space the drums). You can remove the side shields and install an 8" screw-on convex or flat foam polshing head. 8 assorted grit silicon carbide belts to get you started. Each wheel has its own independent water drip spray bar (yes that's right), valve and all new tubing. All you need is to drill out a container, glue the tubing to it or drill a hole and screw a couple dollar barb fitting in (my preference). Essentially you're getting $450 worth of new drums, motor, and belts, and a $100 machine :D

Pickup here Oregon City OR or I can meet you in the Portland area

Refurbished Lortone FL-15 15" Vibratory Lap for sale! This 15 inch lapidary vibratory lap machine is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, stripped, painted, 2 lap pans (grinding and polishing), bumper rings, new ball supports and springs. Runs perfectly. I'll throw in a grit kit, 60/90, 120, 220, and 400. These are going for ridiculous prices used because Lortone stopped producing them in favor of their ultra-expensive oscillating lap. I'm not that greedy so I'm pricing it well under the only used machine I can find (unrestored machine).

From Lortone: A proven workhorse the FL-15 vibrates at 1600 times per minute giving

consistent and excellent abrasion to your specimen. This comes with 2 each 15" pans, one for grinding and one for

polishing. Each pan includes a 3/8 OD polyethylene tube bumper ring. These pans are made of aluminum and the

polish pan comes with its own polishing pad. Pans are easily removed for changing or cleaning.

Pickup here Oregon City OR or I can meet you in the Portland area

.jpg)

.jpg)

.jpg)

.jpg)

This machine priced to sell and is ready to run right now! The gentleman I acquired it from told me that he bought the machine new, used it a couple times and decided that it didn't match his needs. In addition to what you see from Covington's website below I will give you a supply of belts (5) 220, 2) 100, 2) 400, 2) 600), plus 1 slightly used 220 on the machine, and I added water inlet and outlet hoses. All you need is to drill out a container, glue the tubing to it or drill a hole and screw a couple dollar barb fitting in (my preference). The manual is here.

Description (From Covington's website)

The Mounted Wet Belt Sander has 6" of workspace and is designed to sand, grind, and polish small items. This sander comes complete with a 1/3hp motor and belt guard mounted on a rustproof aluminum topped Lam-I-Cushion base, instructions, and product guarantee. A water valve and spray nozzle are built in for easy hookup. The water valve takes 1/4"OD plastic tubing for gravity water flow or 1/4" copper tubing for pressure systems. This model ships with the motor attached, ready to plug in and operate.

Features

Uses 3" x 24" Sand Belts

Upright bearing support casting mounted on a cast aluminum tank

All sanders are available in 220V, 50Hz for use outside of the United States

Unobstructed access to work area

Quick change belt system

Powder coated hood, base, and bearing support

Single control alignment to keep belt running true

Shielded bearings, double sealed and greased for life

Adjustable back plate sands flat surfaces

Pickup here Oregon City OR or I can meet you in the Portland area

.jpg)

.jpg)

.jpg)

.jpg)

Refurbished Star Diamond GP-6 for sale! This 6-inch lapidary cabochon machine is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, stripped, painted, set on a super heavy duty base with a almost new 1/4HP motor. 2 silicon carbide wheels, 80 grit and 180 grit. Expando-type drum sander, screw-on convex foam polshing head with a cowhide cover. 8 silicon carbide belts for the drum sander to get you started (2 each of 220, 400, 600, 800 grit). Unscrew the polishing head when you're sanding and screw it in to polish with oxide polishing compound. You can change the drum belts without removing anything. New belt and low hours (as in less than 2) 1/4 HP motor, new wiring and switch. Each wheel has its own independent water drip valve and all new tubing. All you need is to drill out a container, glue the tubing to it or drill a hole and screw a couple dollar barb fitting in (my preference).

Pickup here Oregon City OR or I can meet you in the Portland area

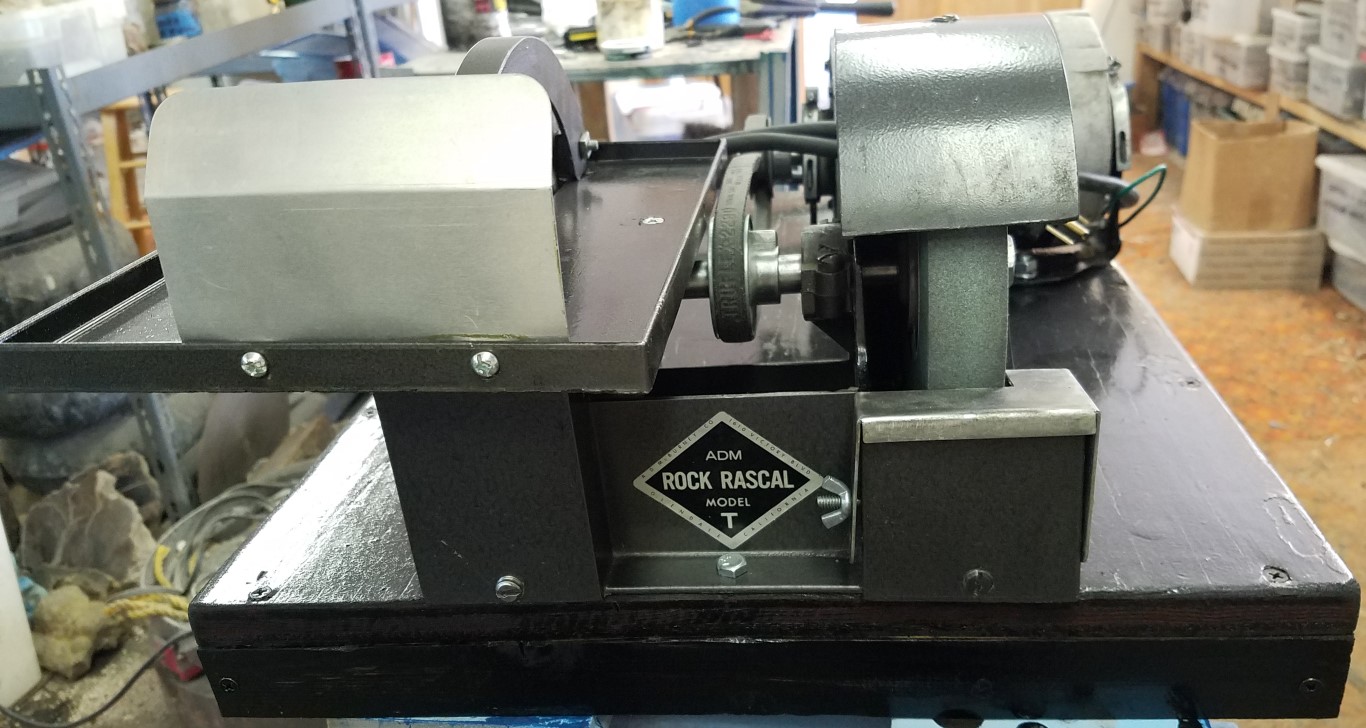

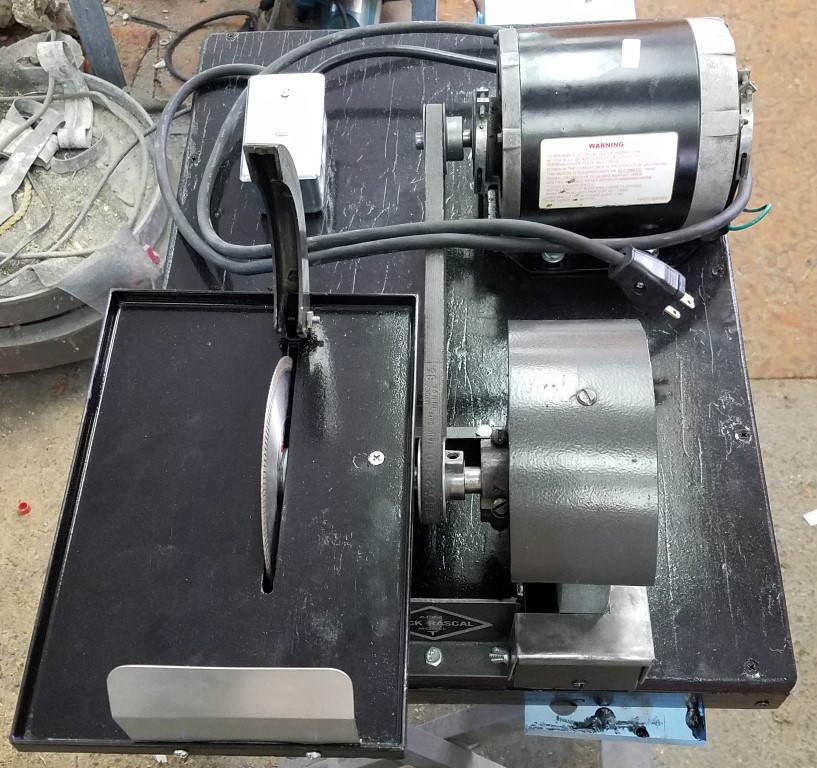

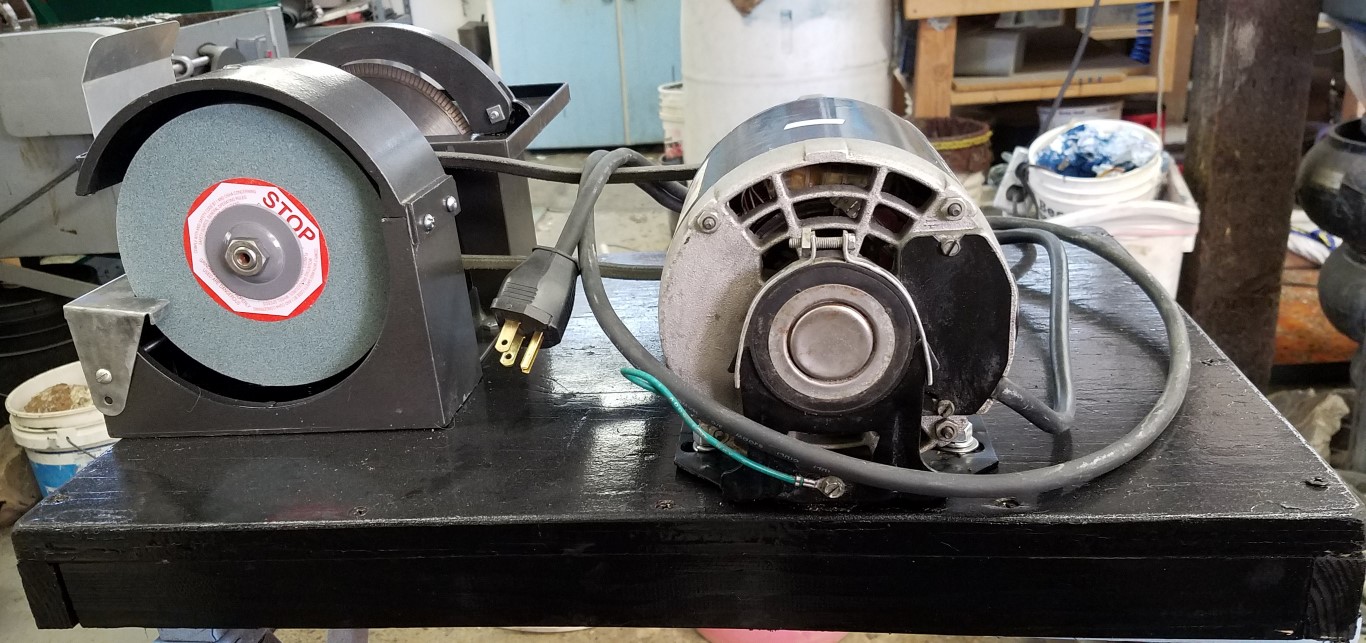

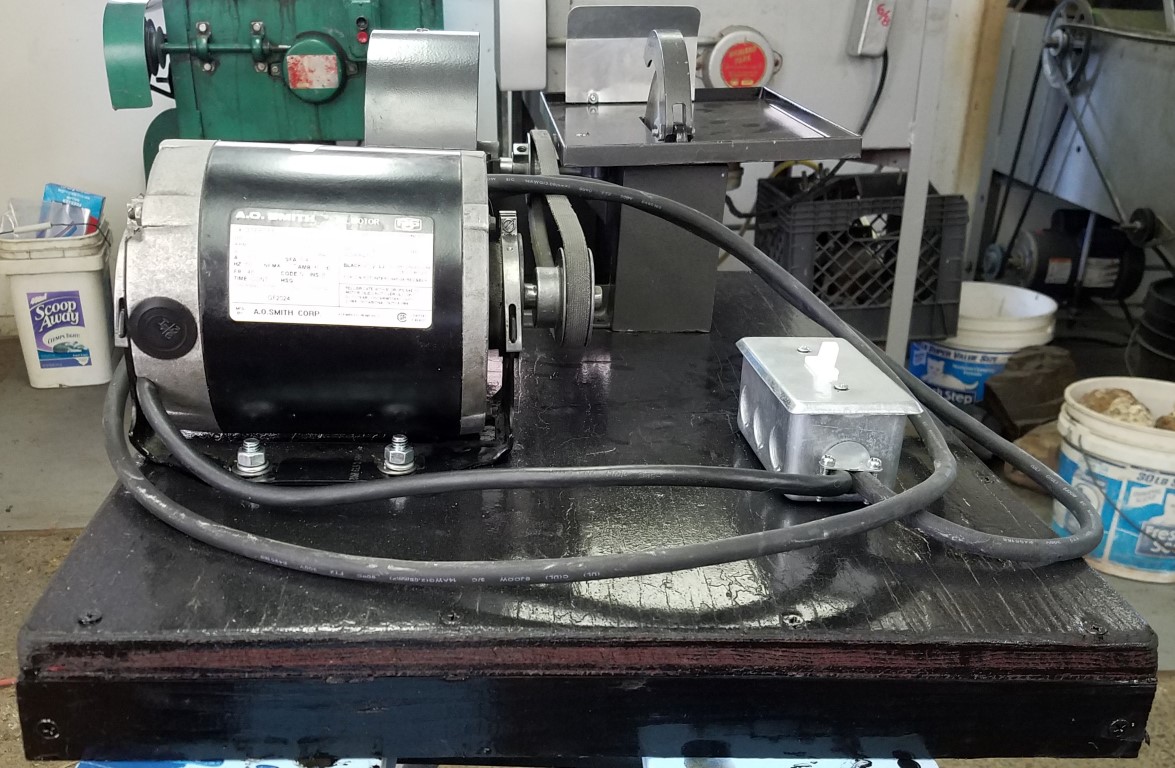

This is essentially a new machine, complete and ready to run. I cleaned it up painted it and mounted it on a super heavy duty base with a motor. The Rock Rascal Model T has a trim saw on the left and a grinding wheel on the right. You can switch out grinding wheels easily. The saw table and inside of the grinding wheel housing are painted with appliance epoxy for extra durability. The motor has a few hours on it. All wiring is new and heavy duty. The trim saw blade is a new Barranca Diamond 6" diamond segmented blade. I added a switch for your convenience. For comparison, this is the breakdown of a new nmachine.

You can add a water feed for the grinding wheel through the hole in the hood but a simple sponge in the pan and water is all that's really needed. YOU MUST USE WITH AN ANTI-RUST ADDITIVE. I have Crystal Kut, which I don't think is available anymore. Several lapidary websites sell their own additives. Graves has Lube Cool which is a good one. Drain both every time you are done using them!

Pickup here Oregon City OR or I can meet you in the Portland area

Refurbished Covington 8" cabochon machine for sale! This 8-inch lapidary cabochon machine is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, stripped, painted, set on a super heavy duty base. 2 silicon carbide wheels, 80 grit and 180 grit. New expando-type drum, screw-on foam polshing head with a new leather cover. You can glue another sanding disk to it with contact cement if you already have a polisher, or use a canvas cover with diamond slurry. 4 belts for the drum to get you started (220, 320, 400, 600 grit). You can change the drum belts without removing anything. New belt and new 1/3 HP motor. Each wheel has its own independent water drip valve. All you need is to drill out a container, glue the tubing to it or drill a hole and screw a couple dollar barb fitting in (my preference).

Pickup here Oregon City OR

Refurbished Star Diamond GP-6 for sale! This 6-inch lapidary cabochon machine is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, stripped, painted, set on a super heavy duty base. 2 silicon carbide wheels, 80 grit and 180 grit. New expando-type drum, screw-on convex foam polshing head with a leather cover. You can glue another sanding disk to it with contact cement if you already have a polisher, or use a canvas cover with diamond slurry. 4 belts for the drums to get you started (220, 320, 400, 600 grit). Unscrew the polishing head when you're sanding and screw it in to polish with oxide polishing compound. Many people put it on medium and leave it there, so that's where I have it set up. You can change the drum belts without removing anything. New belt and 1/3 HP motor which is overkill for the machine. Each wheel has its own independent water drip valve and new rubber spray shields. All you need is to drill out a container, glue the tubing to it or drill a hole and screw a couple dollar barb fitting in (my preference).

Pickup here Oregon City OR

Refurbished Star Diamond Super GP-8 for sale! I've never seen one of these before and may not ever again. I think people hold on to them for dear life. This 8-inch lapidary cabochon machine is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, stripped, painted, set on a super heavy duty base. 4 diamond wheels, 100 grit hard and 120 grit soft. The hard wheel has probably more than 50% diamond left, the soft wheel was never used. 2 like new expando-type drums, screw-on convex foam polshing head with a new leather cover. You can glue another sanding disk to it with contact cement if you already have a polisher, or use a canvas cover with diamond slurry. 4 belts for the drums to get you started (220, 320, 400, 600 grit). Unscrew the polishing head when you're sanding and screw it in to polish with oxide polishing compound. 3 speed adjustable pulley for fast (diamond wheels), medium (sanding wheels), and slow (polishing head). The motor slides on its own base to adjust the belt for each speed. Many people put it on medium and leave it there, so that's where I have it set up. You can change the drum belts without removing anything. Great condition 1/2 HP motor which is overkill for the machine, new wiring and switch. New bearings on the shaft, so it purrs like a kitten :) Each wheel has its own independent water drip valve and new rubber spray shields. All you need is to drill out a container, glue the tubing to it or drill a hole and screw a couple dollar barb fitting in (my preference).

Pickup here Oregon City OR

Refurbished Lortone Model LU-6 for sale! This 6-inch all-in-one lapidary trim saw and lapidary arbor is totally refurbished by me, and ready to run right now! Here's the details: Completely disassembled, stripped, painted, epoxy coated trim saw table and inside of the arbor for extra durability. Trim saw with a hand feed and good used blade. 6" 100 grit silicon carbide wheel (the green wheel is for lapidary use). NEW 6" expando type sanding drum with 4 belts to get you started (220, 400, 600 and 1000). Unscrew the polishing head and change belts without removing the drum. Foam pad polishing head, put a hide or canvas cover on it and use cerium oxide. Or you can glue another sanding disk to it with contact cement if you already have a polisher. NEW 1/4 HP Marathon motor (I know it looks like it isn't level but it is). New water supply system with valves (even the current model doesn't come with them). All you need is to drill out a container, glue the tubing to it or screw a couple dollar fitting in (my preference). (The current model retails new for a little under $800!)

Pickup here Oregon City OR

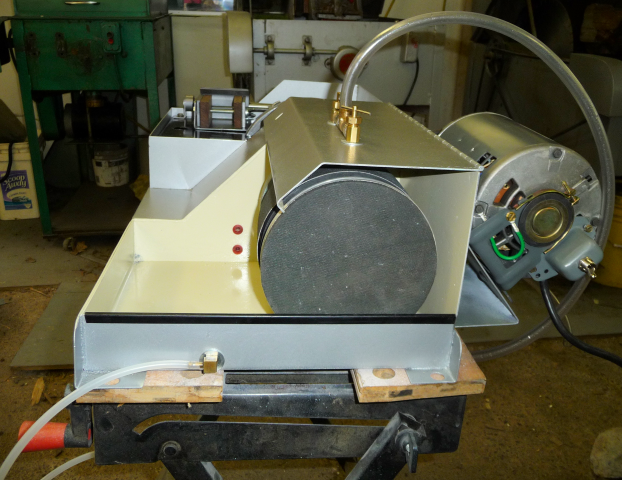

I use one of these machines about every time I'm in my shop. It's for rapidly sanding flat pieces, like cut thundereggs, agate, petrified wood, etc. before you polish them. This one is built like a tank, it's a knockoff of a commercially available machine. Someone knew exactly what they were doing and did an excellent job. All I did was give it a makeover.It uses standard 7" sanding disks that attach to the backing pad with a lock nut. I'll throw in a collection of different grits to get you started (40, 60, 100, 220 and 400 grit). A typical progression would be 36 grit to 100 to 220 or 60 grit to 220. 400 is usually last but once you get the hang of it you can easily go from 60 to 220 to polish. I use a low speed buffer which is ideal for polishing rocks sanded with this machine. The motor is virtually new, the electrical system is top notch, it's wired exactly like I would do it lol. has an extra outlet on the back for plugging in other machines. Changing sanding disks is easy, jut loosen the nut with the tool and switch disks. This setup is vastly superior to the "glue on" sanding disks which take forever to change and require a separate backing disk for each grit. It has an adapter for a shop vac (use with HEPA filter) or shop exhaust that is mandatory for using these, they generate a ton of silica dust which is very bad for your health. Has a 1/2 HP 3450 RPM motor. I can give you a quick lesson on my machine if you aren't sure how to use it. I have plenty of tips & tricks with 25 years of experience! (The commercial model retails new for $495!)

Pickup here Oregon City OR or I can meet you in the Portland general area

This is the best reconditioned Genie you are likely to ever find for sale! Complete machine for cabochon making, from grinding to polishing. It came to me from a friend's estate and he had tons of rock, thousands of slabs, and a hundred or so cabochons. In other words he liked to dig rocks, slab them, cab some of them, then lost interest in the hobby. So the machine was lightly used to start with. Here's the details:

New base straight from the original shipping box. Pristine motor, 6 used wheels in excellent condition: 80 & 220 mesh hard diamond wheels, 280, 600, 1200 and 14000 mesh soft diamond wheels. A convex polishing pad screws into the right side, you can use it with diamond paste or just glue on a felt pad with rubber cement for cerium oxide. The right side of the shield is removable so you can use the polishing pad (I added wingnuts, makes it much faster to use). Water spray pump updated with new parts from the manufacturer. The knob in the front switches between left and right spray heads. The newer models don't have this which I think is a mistake. Had the worklight and the optional magnifier (you will use this!). Has a cabochon rest for shaping, and the shields and pans have been painted and clearcoated, and the inside of both is sprayed with epoxy for extra durability. There is a little bit of plastic repair on the removable side spray shields. I can give you a quick lesson on my machine if you aren't sure how to use it. I have plenty of tips & tricks with 25 years of experience!

(The current model retails new for around $1900!)

Pickup here Oregon City OR

OreRockOn Rock Dig Locations DVD NEW VERSION 8!

OreRockOn Rock Dig Locations DVD NEW VERSION 8! Lapidary Materials, Faceting Rough, Fossils, and More for Sale

Lapidary Materials, Faceting Rough, Fossils, and More for Sale

Lapidary Arts Instruction Classes

Lapidary Arts Instruction Classes

Rock Cutting and Polishing Services

Rock Cutting and Polishing Services

Polished Agates for Sale

Polished Agates for Sale

Polished Thundereggs for Sale

Polished Thundereggs for Sale

Faceted Gemstones for sale

Faceted Gemstones for sale

Cabochons for Sale

Cabochons for Sale

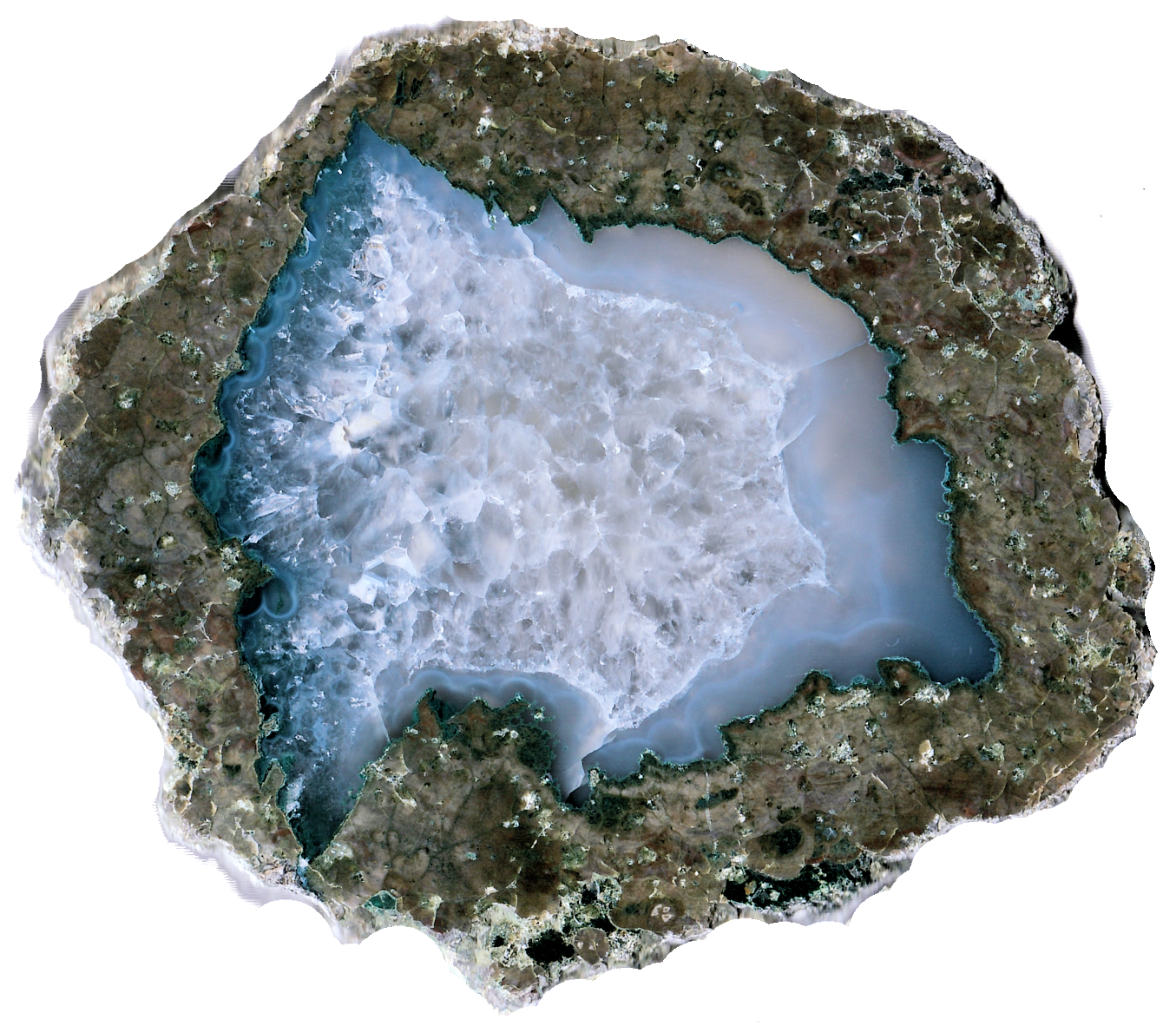

Rock Crystal Geodes for Sale

Rock Crystal Geodes for Sale

Rock Display Stands for Sale

Rock Display Stands for Sale

Rock & Lapidary Bookstore

Rock & Lapidary Bookstore

Back to

Ore-Rock-On!

Back to

Ore-Rock-On!Copyright © 1997 - 2024

Tim FisherUsers may download this World Wide Web page for personal use only. Unauthorized copying or distribution of this page or any of its contents without the express permission of the author is expressly forbidden.